MacSync-LNC-Xx Datasheet

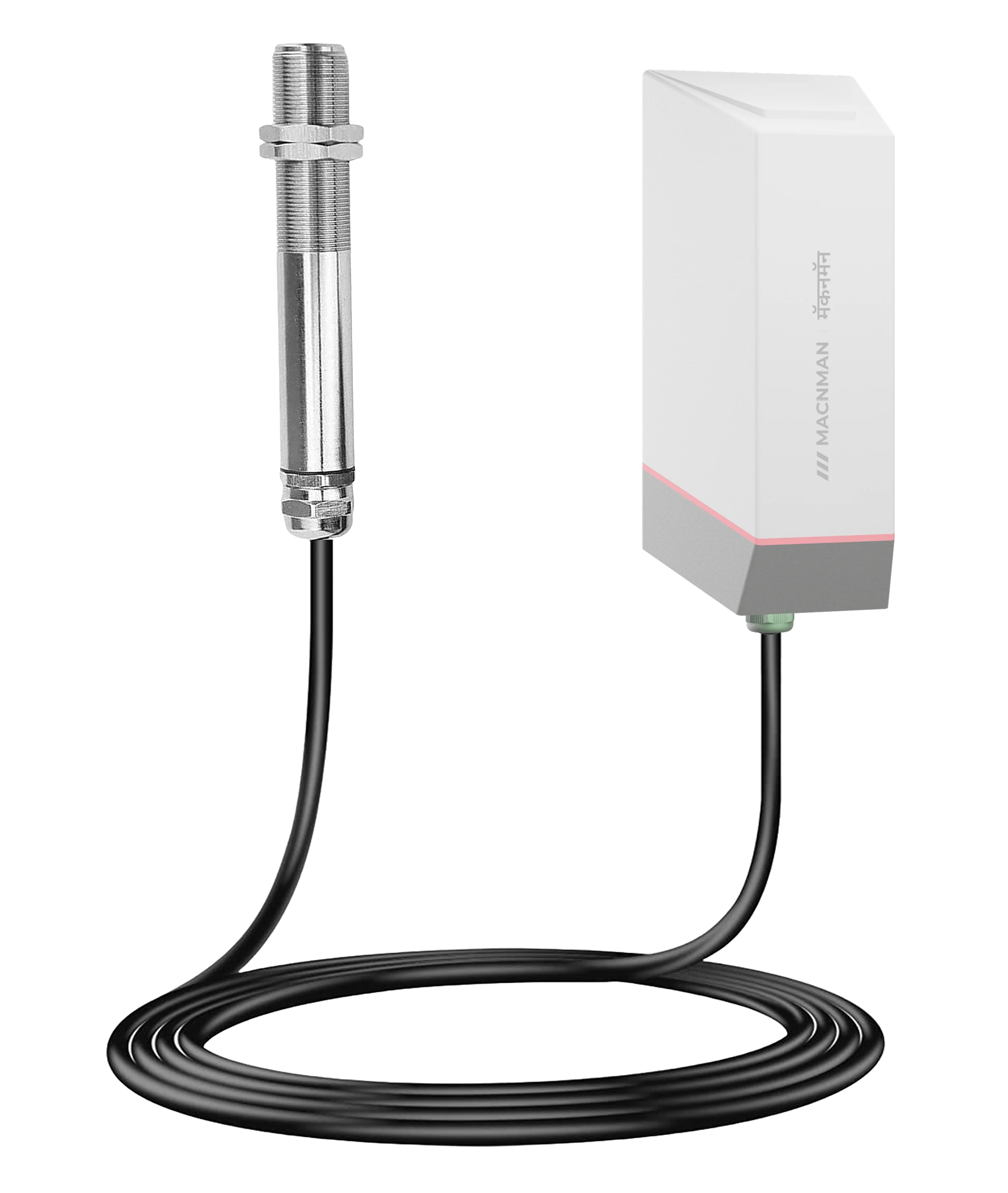

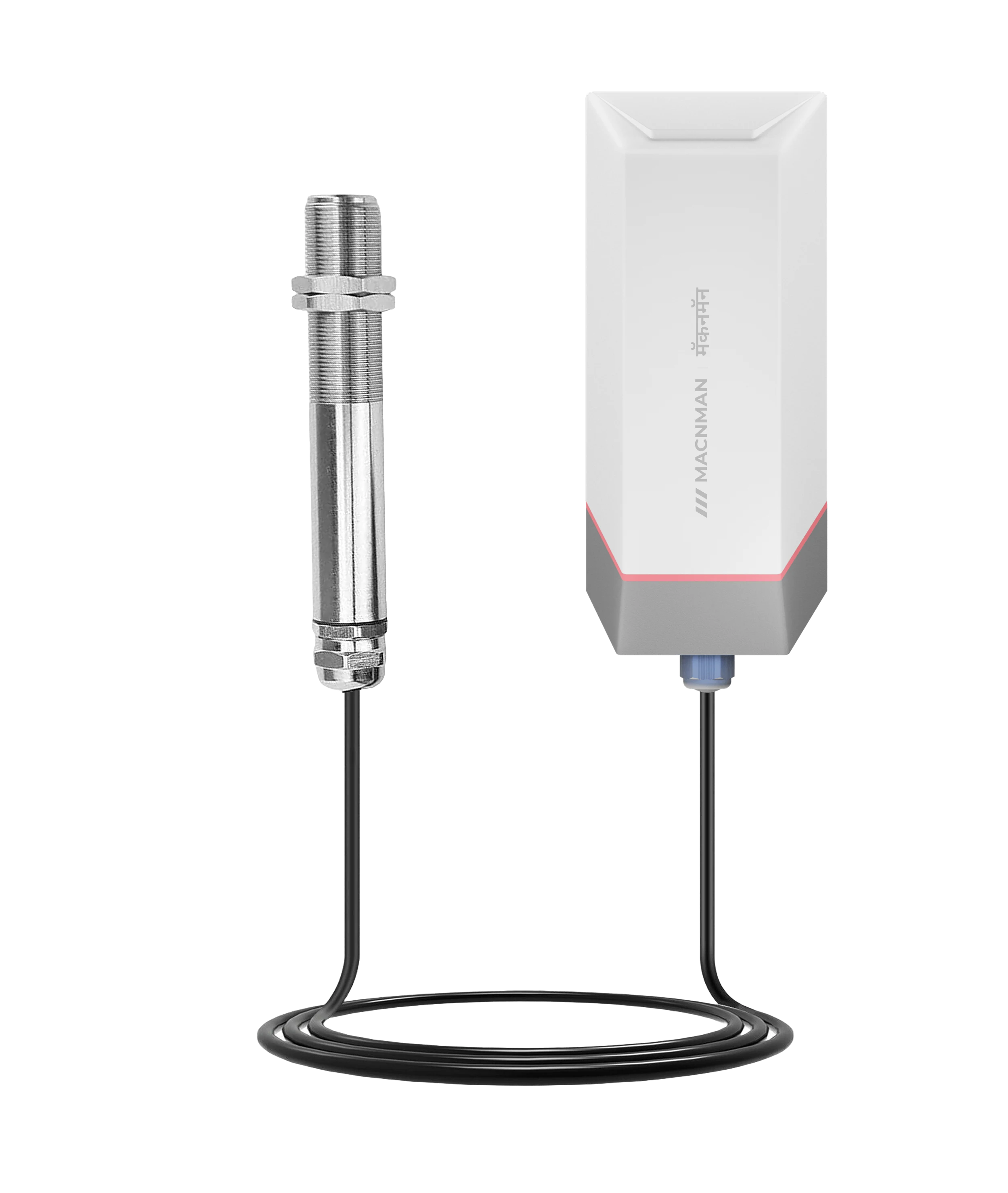

Product Overview

MacSync-LNC-Xx is an industrial-grade non-contact laser (infrared) temperature sensor engineered for accurate surface temperature monitoring in extreme, moving, hazardous, or hard-to-reach environments. By measuring infrared thermal radiation instead of physical contact, it enables safe and reliable temperature sensing of hot, rotating, electrified, or inaccessible surfaces without mechanical wear, probe failure, or process interruption.

Designed for harsh industrial deployments, the MacSync-LNC-Xx delivers fast response, stable readings, and repeatable performance across high-temperature process environments such as furnaces, kilns, rolling mills, conveyors, transformers, reactors, boilers, and power equipment. The integrated laser targeting system ensures precise spot measurement, allowing accurate temperature capture even on small, fast-moving, or distant objects.

The device features LoRaWAN® Class A/C long-range wireless connectivity, AES-128 encrypted data transmission, and an ultra-low-power architecture optimized for multi-year battery operation. Integrated BLE configuration via the Macnman Maya App enables rapid commissioning, emissivity configuration, OTA parameter updates, and diagnostics — eliminating manual calibration and reducing on-site maintenance effort.

Housed in a rugged IP65/IP67-rated industrial enclosure, the MacSync-LNC-Xx is built to operate reliably in dusty, high-vibration, high-EMI, and outdoor environments. Optional external DC power input and flexible industrial mounting options make it suitable for both fixed installations and remote monitoring applications.

Ideal for predictive maintenance, thermal safety monitoring, process optimization, and Industry 4.0 automation, MacSync-LNC-Xx transforms non-contact temperature measurement into a smart, wireless, and scalable IoT sensing solution, delivering real-time thermal intelligence across industrial and smart infrastructure deployments.

|  |

|---|---|

|  |

Download Center

Download the PDF Version of the Datasheet .

Click here to view the decoders for MacSync-LNC-Xx

Key Features

Non-Contact Infrared (Laser-Assisted) Temperature Sensing Measures surface temperature without physical contact, enabling safe and accurate monitoring of hot, moving, live, or inaccessible objects.

Extreme Temperature Measurement up to 1500 °C Designed for high-temperature industrial environments such as furnaces, kilns, rolling mills, foundries, and power equipment.

Ideal for Moving & Hazardous Targets Accurately monitors rotating shafts, conveyors, molten surfaces, and electrically live equipment without sensor wear or process interruption.

Industrial-Grade IP65 / IP67 Enclosure Rugged housing ensures reliable operation in dusty, high-vibration, high-EMI, and outdoor industrial environments.

Flexible Uplink & Reporting Strategies Supports periodic, threshold-based, and event-driven uplinks to optimize network traffic, alerting, and battery life.

Ultra-Low Power Design with 19Ah Battery Powered by an industrial-grade lithium battery, delivering up to 10+ years of operational life depending on configuration.

BLE Configuration via Macnman Maya App Enables quick local setup, emissivity adjustment, diagnostics, and OTA parameter updates without opening the enclosure.

Secure LoRaWAN® Connectivity Uses AES-128 encrypted communication with secure onboarding via pre-flashed DevEUI, AppEUI, and AppKey.

Supports Macnman Beam Protocol Enables direct control, local device-to-device actions, and edge-level automation without continuous cloud dependency.

Optional Onboard Data Buffering Prevents data loss during network outages by storing records locally and synchronizing automatically once connectivity is restored.

Universal LoRaWAN® Network Compatibility Fully compatible with all standard LoRaWAN® network servers and gateways, including private and public LNS deployments.

Built for Predictive Maintenance & Industry 4.0 Delivers real-time thermal intelligence for early fault detection, safety monitoring, and process optimization.

Suited Applications

High-Temperature Industrial Process Monitoring Non-contact infrared temperature measurement for furnaces, kilns, ovens, reactors, and thermal processing equipment where direct sensors cannot survive.

Steel, Foundry & Metallurgical Operations Continuous surface temperature monitoring of molten metal, billets, slabs, and rolling mills to improve safety, quality control, and process efficiency.

Power & Energy Infrastructure Remote thermal monitoring of transformers, switchgear, busbars, turbines, boilers, and substations to prevent overheating and unplanned outages.

Conveyor Belts & Moving Equipment Accurate temperature sensing of fast-moving or rotating assets such as conveyor belts, rollers, motors, and shafts without physical contact.

Hazardous & Electrically Live Areas Ideal for explosive, high-voltage, or unsafe zones where wired probes and manual inspection pose serious safety risks.

Predictive Maintenance & Condition Monitoring Early detection of abnormal heat signatures to identify bearing failure, insulation breakdown, friction losses, and equipment degradation.

Mining, Cement & Heavy Industries Reliable non-contact temperature monitoring in dusty, high-vibration environments such as mines, crushers, clinker coolers, and cement kilns.

Remote & Outdoor Industrial Assets Long-range LoRaWAN® connectivity enables temperature monitoring of isolated assets where power and wired networks are unavailable.

Industry 4.0 & Smart Factory Deployments Enables data-driven automation, thermal analytics, and digital transformation by integrating surface temperature data into IoT platforms.

Technical Specification

General

Specifications

Part Order Number

MacSync-LNC-Xx

Product Brand

Macnman Technologies Pvt Ltd

Temperature

Measurement

Sensor Type

Infrared (Non‑Contact) Temperature Sensor

Measurement Range

0 °C to 600 °C (Standard)

0 °C to 1500 °C (High‑Temperature Variant)

Accuracy

±1 % of reading or ±1 °C (whichever is greater)

Resolution

0.1 °C

Repeatability

±0.5 % of reading

Optical Resolution (D:S)

15 : 1 (Standard)

30 : 1 (Optional)

Spectral Response

8 – 14 µm

Response Time (95 %)

< 250 ms

Emissivity Adjustment

0.10 – 1.00 (Configurable)

Power Supply

12 – 24 V DC

Power Consumption

< 50 mA (Typical)

Wireless

Transmission

Wireless Protocols

LoRaWAN® (v1.0.4)

Macnman MacTalk Protocol

Antenna

Internal high-efficiency antenna

Supported Bands

IN865 / RU864 / EU868 / US915 / AU915 / KR920 / AS923-1/2/3/4

Tx Power

26 dBm @ 868 MHz / 20 dBm @ 915 MHz / 19 dBm @ 470 MHz

Sensitivity

-137 dBm @ 300 bps

Activation

OTAA

LoRaWAN® Class

Class A (default)

Configurable to Class C via Maya

LED

Status

LED Type

1 Internal Multi-Color LED

Solid Blue

Device is connected with Maya App

Flashing Blue

OTA (Over-the-Air) update in progress

Slow Blinking Green

Attempting to connect to the LoRaWAN® network

Single Red Blink

A confirmed parameter of MacSync is being modified

Device

Configuration

Configuration

Via Macnman Maya Android App

Uplink Modes

Time Based / Threshold Based / Sampling Based

Stored Records*

30,000 Records

Remote Configuration

JSON Format Data - from server

Battery

Performance

Battery Type

Li-SOCl₂ Cell (19Ah) Industrial grade

Power Consumption

~100 µA in sleep mode

~50 mA during transmission

Battery Life

Up to 10 years (10 Mins Uplink Interval)

Supported

LNS

Supports Major LNS

Private LNS

Chirpstack

The Things Networks

MQTT

Orbiwise

LORIOT

Direct PLC On-Prim Installations

Physical

Characteristics

Power Supply (Optional)

9-36 V DC

Operating Temperature

-40°C to +80°C

Humidity Range

0% to 100% RH (non-condensing)

Ingress Protection

IP65 standard (IP67 optional variant)

Housing Material

Glass field Nylon

Color

Matte White

Weight

~110g

Mounting Options

Pole Mounting / Wall Mounting

Electrical

Characteristics

Input Voltage Range (Optional Varient)

9-36 V DC (External Supply)

Power Consumption

~100 µA in sleep mode

~50 mA during transmission

Input Impedance

>10 MΩ for voltage inputs

Communication

Options

BLE Connectivity

For local configuration and diagnostics via Maya App

Cloud Protocols

MQTT / HTTPS / TCP IP (Gateway Dependent )

Serial Interface

RS485 Modbus RTU support (optional)

Certifications &

Compliance

WPC

Compliant

RoHS

Conforms to RoHS directive

Security &

Encryption

Data Encryption

AES-256 end-to-end encryption

Authentication

OTAA activation modes

Firmware Protection

Secure boot and signed OTA updates

MacSync-LNC-Xx Variants

| Variant Code | Temperature Range | Power Source | Battery Capacity | Ideal Use Case |

|---|---|---|---|---|

| MacSync-LNC-X1-PO | Up to 150 °C | 12–24 V DC (External Power) | — | Low-temperature industrial surfaces, machinery, and process equipment |

| MacSync-LNC-X1-BO | Up to 150 °C | Battery Operated | 19 Ah | Remote assets and installations with no external power availability |

| MacSync-LNC-X2-PO | Up to 300 °C | 12–24 V DC (External Power) | — | Medium-temperature processes, conveyors, motors, and rotating equipment |

| MacSync-LNC-X2-BO | Up to 300 °C | Battery Operated | 19 Ah | Battery-powered monitoring of moving or hard-to-wire assets |

| MacSync-LNC-X3-PO | Up to 600 °C | 12–24 V DC (External Power) | — | High-temperature industrial equipment such as ovens, dryers, and heaters |

| MacSync-LNC-X3-BO | Up to 600 °C | Battery Operated | 19 Ah | Remote high-temperature assets requiring long battery life |

| MacSync-LNC-X4-PO | Up to 1200 °C | 12–24 V DC (External Power) | — | Steel plants, foundries, furnaces, kilns, and metallurgical processes |

| MacSync-LNC-X4-BO | Up to 1200 °C | Battery Operated | 19 Ah | Remote furnace and kiln monitoring where wiring is impractical |

| MacSync-LNC-X5-PO | Up to 1500 °C | 12–24 V DC (External Power) | — | Extreme-temperature applications such as molten metal and high-energy furnaces |

| MacSync-LNC-X5-BO | Up to 1500 °C | Battery Operated | 19 Ah | Wireless extreme-temperature monitoring in hazardous or inaccessible areas |

What's in the box ?

Make sure box contains following items before installations

Accessories must be purchased separately & may not be included in the box.