Industrial Drainage Monitoring & Automatic Pump Control

In industrial plants, the most dangerous problems are often the ones you don’t see coming.

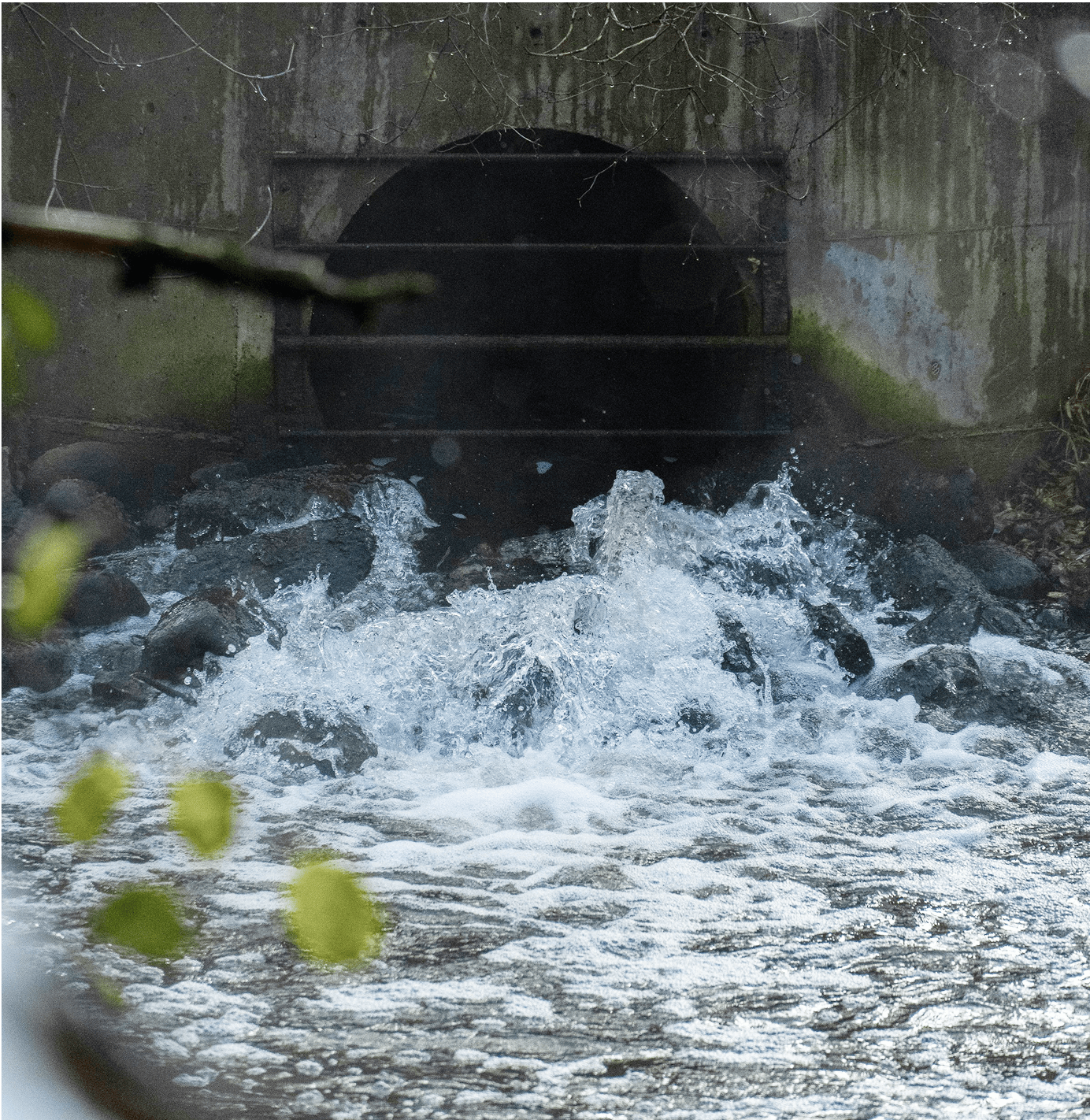

One of the biggest hidden threats sits under the floor clogged or overloaded underground drainage lines. When water starts rising silently, it doesn’t take long to create a mess: equipment downtime, material damage, unsafe walkways, and full operational disruption especially during heavy rainfall, cleaning cycles, or peak discharge hours.

To eliminate this blind spot, Macnman Technologies deployed an IoT-based ultrasonic water level monitoring system(MacRay) built specifically for industrial drainage networks. Using MacSet LoRaWAN Controllers, long-range LoRaWAN gateways, and industrial-grade ultrasonic level sensors, the plant now gets continuous real-time drainage level visibility without manual inspection. The result: faster action, smarter pumping decisions, and safer operations before water turns into a hazard.

Problem: Rising Water Levels Hidden Underground

In a steel processing plant, water is not just “water” it becomes a serious operational risk the moment it starts collecting in the wrong place. The drainage system runs underground, out of sight, and when a line gets partially clogged or the flow suddenly increases, water levels rise silently until the plant feels it the hard way: wet floors, blocked movement, equipment risk, and emergency shutdown situations.

The biggest problem was no real-time visibility. The team had to depend on manual checks and late alerts, which meant pumps were started only after water had already crossed a dangerous level. During heavy rainfall or high-discharge cleaning cycles, this delay could quickly turn into a hazardous condition, affecting safety, uptime, and day-to-day production continuity.

Blocked Drains

Sediment buildup and industrial waste caused unexpected clogs, leading to water overflow and flooding during cleaning or rainfall.

Manual Monitoring

Maintenance teams had to physically open chambers to check water levels — time-consuming, risky, and inconsistent.

No Real-Time Visibility

Without continuous monitoring, drainage health could only be guessed, not measured.

Safety Concerns

Standing water near power units and control panels created electrical hazards and unsafe working conditions.

Solution: Preventing Water Hazards with LoRaWAN Level Sensors and Motor Control

To stop drainage overflow from turning into downtime, we built a system that works before the water becomes visible. Instead of relying on manual inspection, we deployed our LoRaWAN ultrasonic water level sensor connected with the MacSet LoRaWAN controller, creating a continuous monitoring + control loop for underground drainage points.

The real upgrade wasn’t just monitoring it was automation. Using intelligent threshold-based logic, the system starts the pump motor automatically the moment water reaches the defined level, and keeps the drainage under control without waiting for human intervention. This approach delivers exactly what steel plants need: real-time drainage visibility, proactive flood prevention, safer floors, and uninterrupted operations.

- 01

Ultrasonic Water Level Sensors

Industrial-grade ultrasonic sensors detect the exact water depth in underground drainage chambers, unaffected by debris, foam, or humidity.

- 02

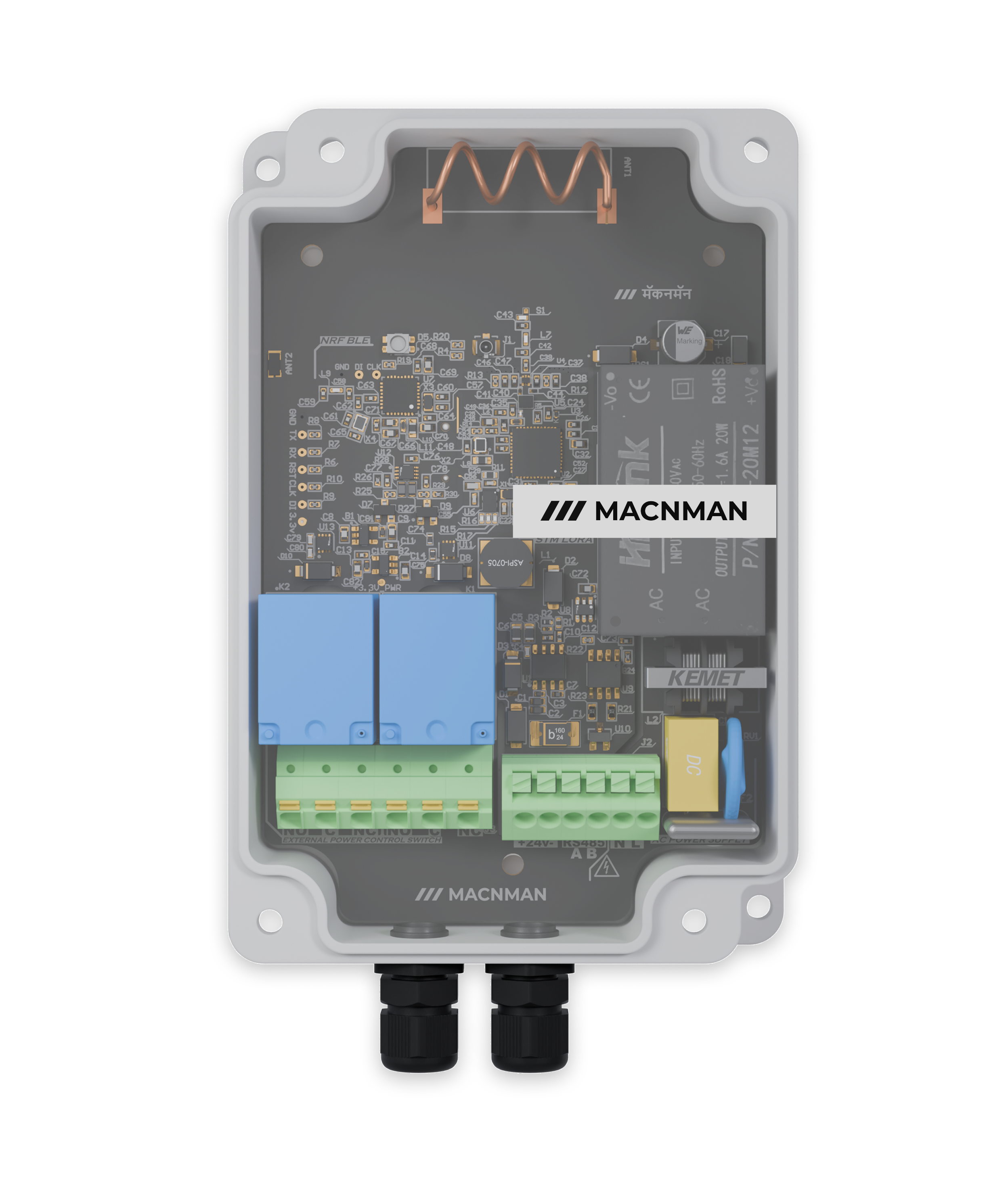

MacSet LoRaWAN Controller

Each controller receives sensor data and triggers the connected pumps automatically when the water level crosses a defined threshold.

- 03

Automated Pump Activation

Smart logic ensures pumps start and stop precisely when needed — preventing both overflow and dry running, optimizing energy use.

- 04

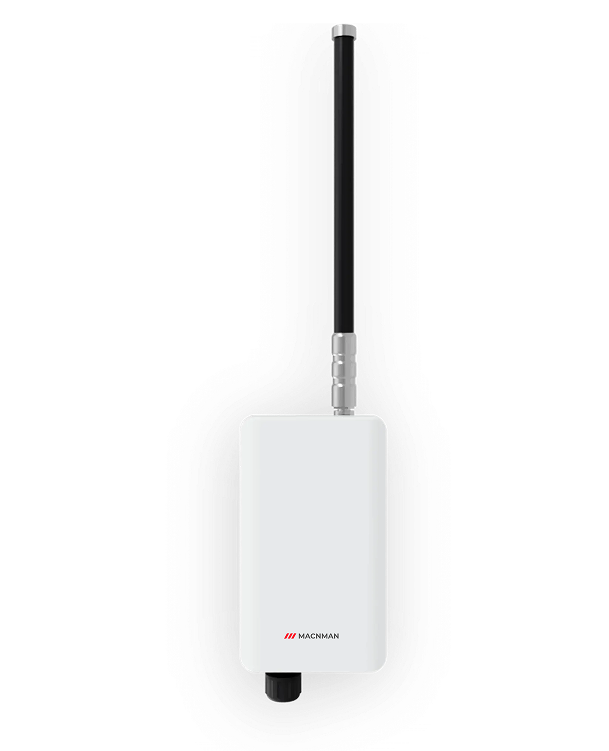

LoRaWAN Gateway Connectivity

All controllers communicate wirelessly to a central LoRaWAN gateway, which sends real-time status updates to the cloud dashboard

- 05

Real-Time Alerts

Supervisors get instant notifications when pumps activate, water levels rise abnormally, or any fault occurs in the drainage system

- 06

Maintenance Planning

Continuous data logging helps identify trends enabling predictive maintenance, early detection of partial blockages, and better pump lifecycle management.

System Architecture: LoRaWAN Ultrasonic Drainage Monitoring with Automatic Pump Control

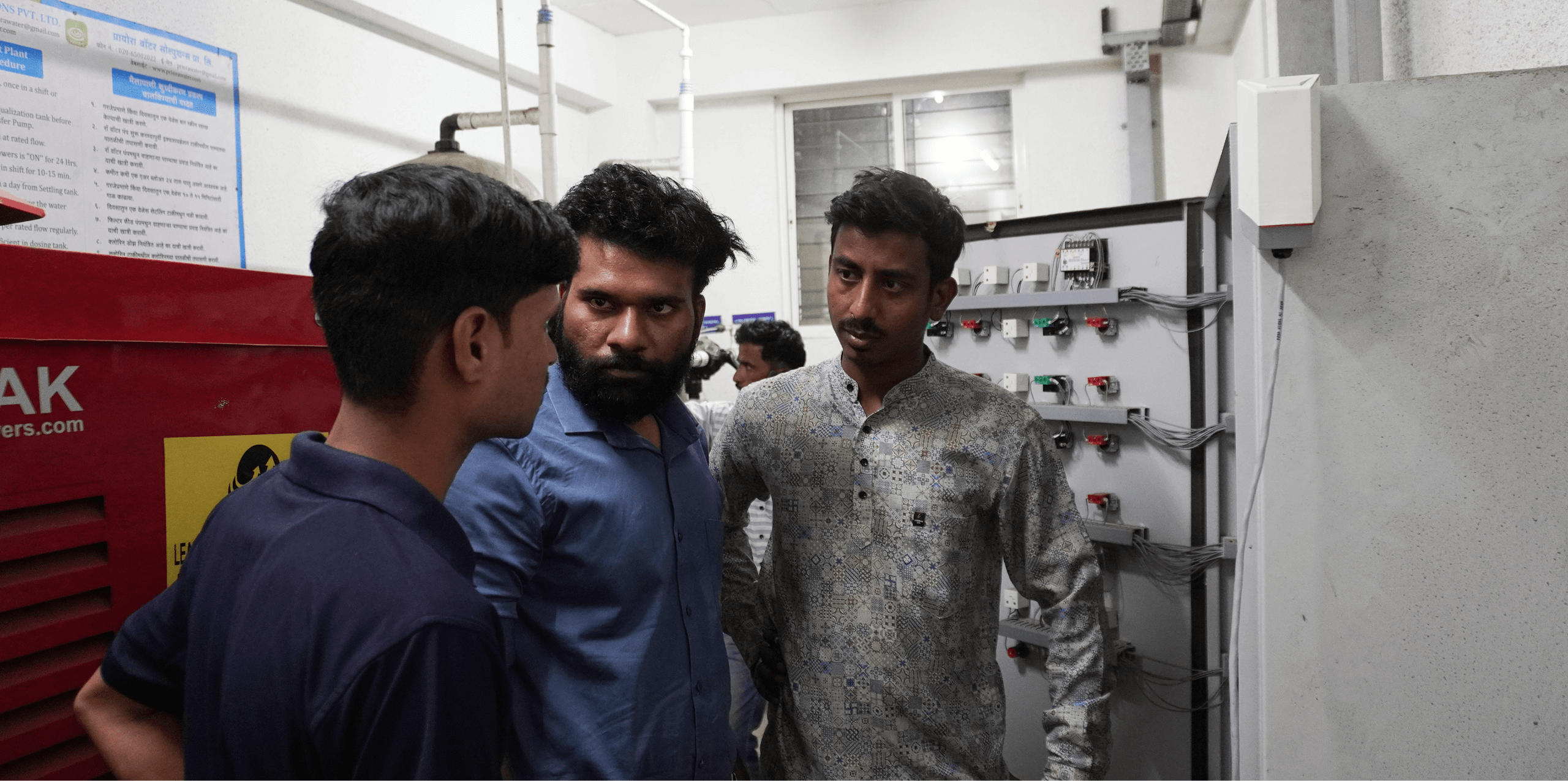

Deployment: Real-Time Drainage Monitoring + Auto Pump Control in Action

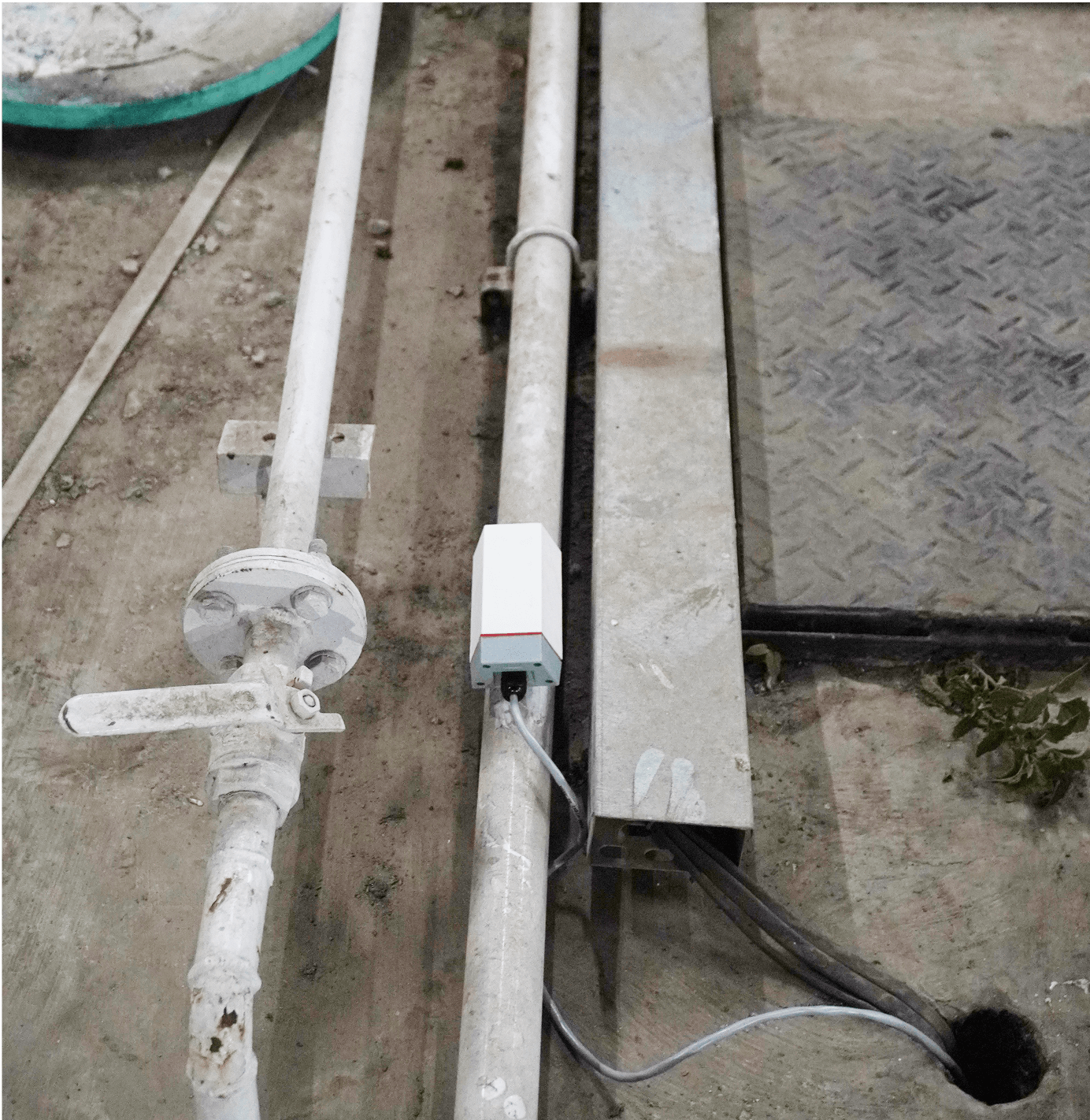

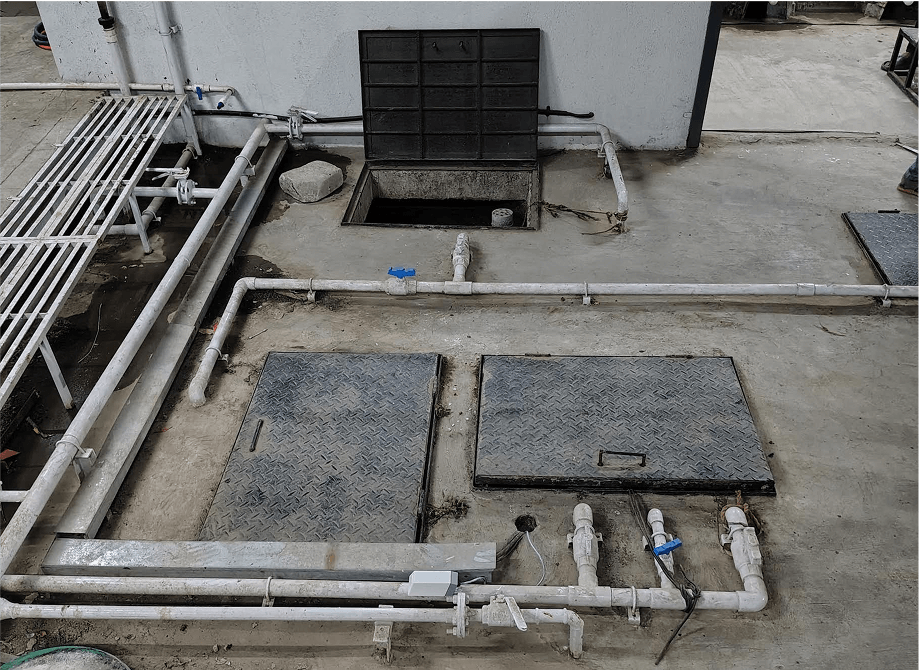

This deployment was executed in a live steel processing environment where drainage issues don’t wait for planned shutdowns. We installed the LoRaWAN ultrasonic water level sensor at critical underground drainage points where water accumulation typically starts, ensuring accurate level measurement even during high-flow conditions like cleaning cycles and heavy rainfall.

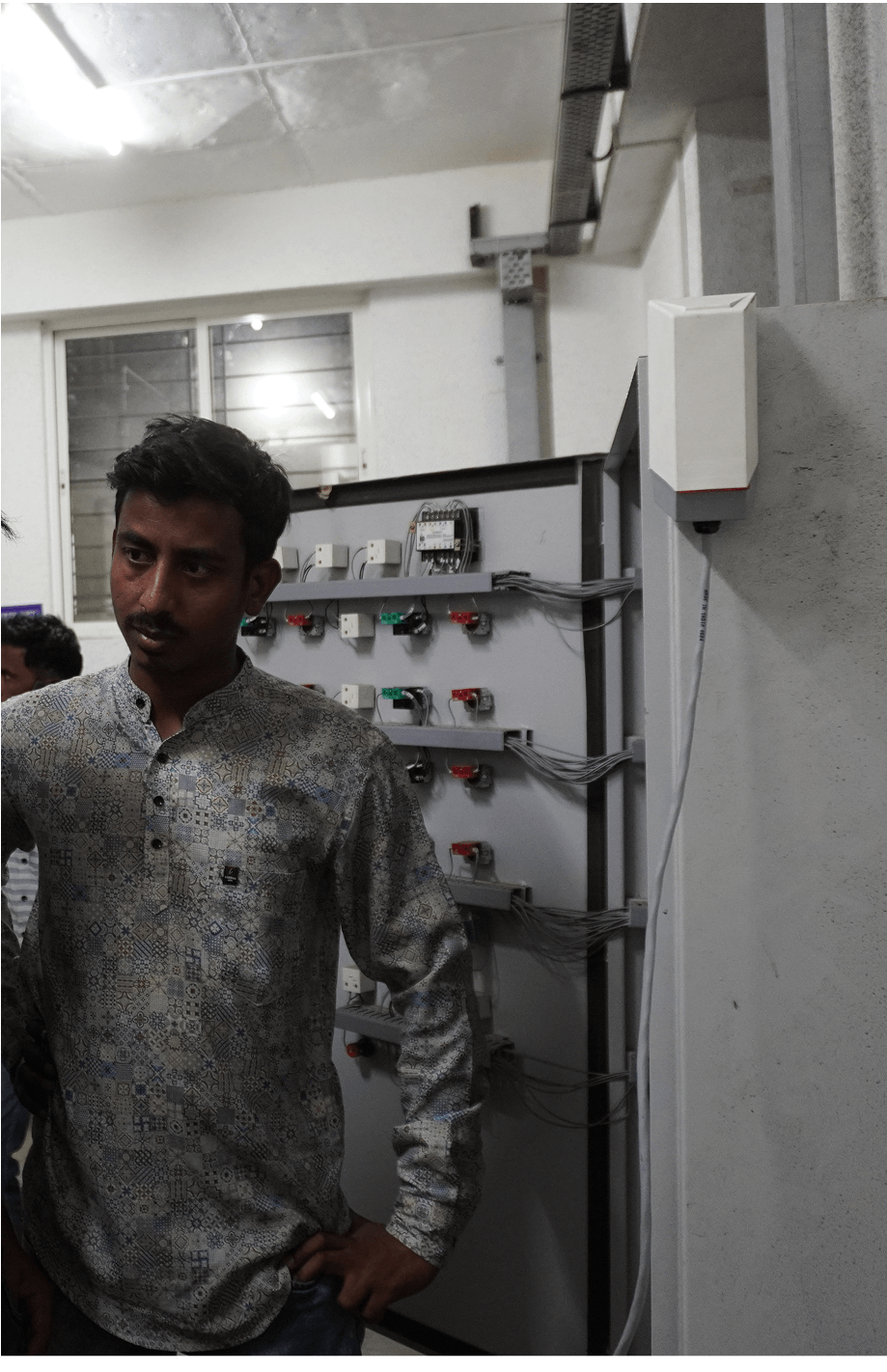

The sensor was integrated with the MacSet LoRaWAN controller, which handled threshold logic and motor control output to automatically start the pump when water reached the set level. With LoRaWAN connectivity and plant-wide coverage, the drainage status became visible in real time, and pumping became automatic, consistent, and proactive preventing overflow before it could turn into a safety hazard or production disruption.

Ultrasonic Sensors

Installed inside each drainage chamber and sump pit , Positioned to avoid debris accumulation and ensure precise water level readings.

LoRaWAN Gateway

Centralized location in the plant ensures long-range, interference-free communication with all controllers.

Relays data to the dashboard/server for monitoring and alerting.

MacSet LoRaWAN Controllers

Mounted near pump stations or accessible control points.

Each controller manages multiple sensors and triggers pumps automatically.

Monitoring Dashboard

Displays live water levels, pump status, and historical trends. Sends automated alerts to supervisors via app, SMS, or email.

Challenges: Automating Drainage Control in a Harsh Steel Plant Environment

Connectivity Gaps 📡

Thick walls, metallic structures, and underground chambers created signal interference.

Harsh Environment 🌦️

Industrial-grade ultrasonic sensors and IP67-rated enclosures guaranteed continuous operation without damage.

Pump Control Precision ⚙️

Incorrect water level thresholds or delayed pump activation could lead to flooding or energy waste.

Sensor Placement Accuracy 🎯

Incorrect positioning in pits caused false readings due to turbulence, foam, or shadows. Each sensor was field-mapped and calibrated for consistent accuracy.

Testing & Validation: Proving Drainage Automation Works in Real Plant Conditions

Sensor Calibration 🎯

Each ultrasonic sensor was calibrated to accurately measure water levels in confined underground chambers, accounting for turbulence, foam, and debris.

Connectivity Verification 📡

LoRaWAN controllers and gateways were stress-tested to ensure reliable, long-range communication in dense industrial environments.

Pump Activation Testing ⚙️

Controllers were tested under varying water levels to confirm precise, automated pump operation, preventing overflow and avoiding dry running.

Durability & Environmental Testing 🌦️

Sensors and controllers were exposed to high humidity, occasional chemical exposure, and dust to validate IP67-rated reliability in industrial conditions.

Impact: Improved Safety and Zero-Delay Drainage Control in Steel Plant Operations

Prevented Overflow & Flooding 🌊

Real-time monitoring and automated pump control eliminated water buildup, reducing operational downtime.

Operational Efficiency Boost ⚡

Automatic pump activation cut manual intervention, saving maintenance labor hours and ensuring uninterrupted workflow.

Energy Optimization 🔋

Pumps operate only when needed, reducing unnecessary electricity consumption by up to 25%.

Improved Safety 🛡️

Early detection of rising water levels prevented equipment exposure and workplace hazards.

Predictive Maintenance Enabled 🛠️

Continuous water level logging helps identify potential drainage blockages before they become critical, reducing emergency repairs.

Conclusion: Automated Flood Prevention for Industrial Plants

This steel plant deployment proved that drainage monitoring isn’t just maintenance it’s a safety and uptime requirement. By combining a LoRaWAN ultrasonic water level sensor with the MacSet LoRaWAN controller, we converted an underground blind spot into a system that can detect rising water early and trigger pumping automatically at the right threshold.

The real value wasn’t only real-time visibility it was automatic action. The plant reduced overflow risk, improved shopfloor safety, and avoided avoidable disruptions during heavy rainfall and cleaning cycles. This is exactly what Macnman builds for: industrial IoT that prevents problems, not just reports them.

Read the Next Case Study: Vehicle performance in Mines