Odor Monitoring in Amazon Warehouses Using LoRaWAN Sensors

Warehouses are built for speed. But when the air quality goes wrong, everything slows down - people complain, teams get distracted, and the operations team is forced to react without any real data.

In our deployment inside Amazon warehouse facilities, the challenge was very specific: Odor events were happening in sensitive zones, especially near washrooms and inside washrooms, where even small spikes become noticeable fast.

And the real issue wasn’t just the smell. It was the lack of visibility:

- When exactly did the odor spike start?

- Which washroom / which nearby zone is impacted?

- Is it a one-time event or repeating every day?

- Is it ventilation related, usage related, or cleaning-cycle related?

To solve this properly, we installed a smart odor monitoring sensors using H2S & NH3 sensors, placed strategically in washroom areas and adjacent warehouse zones.

Now instead of reacting to complaints, the team gets live odor readings, trend history, and instant alerts turning odor control into a measurable, trackable, operational process.

The Challenge : When a Small Odor Issue Becomes a Big Warehouse Problem

In a warehouse like Amazon, even a small odor issue becomes a big operational problem fast especially inside washrooms & the zones near washrooms, where people notice it instantly. The complaints were real, but the bigger issue was simple: no data, no visibility, no proof.

Without continuous monitoring, the facility team was forced to react blindly checking washrooms manually, increasing ventilation, and hoping the smell goes away. That’s why we needed a real-time odor monitoring solution using H2S and NH3 sensors, so the team could track odor spikes, identify hotspots, and act before it turns into a daily issue.

Unnoticed Gas Accumulation

Hydrogen sulfide (H₂S) and ammonia (NH₃) were not tracked continuously, risking employee comfort and safety.

Poor Odor

Dust and odors (PM2.5/PM10) accumulated, affecting cleanliness perception and hygiene standards.

Delayed Alerts

Without real-time monitoring, issues were only detected after complaints, causing delays in maintenance.

Operational Risk

Poor air quality impacted employee satisfaction, safety, and warehouse hygiene.

Smart IoT Solution for Air Quality and Hygiene Optimization

We treated odor like an operational parameter, not a complaint. Our team deployed H2S and NH3 sensing points in washrooms and nearby zones to capture what the human nose can’t quantify how often odor events occur, how long they last, and which locations trigger them the most.

- 01

Continuous AQI Monitoring

Real-time tracking of H₂S, NH₃, and CO₂ levels ensures safe air quality in warehouse washrooms.

- 02

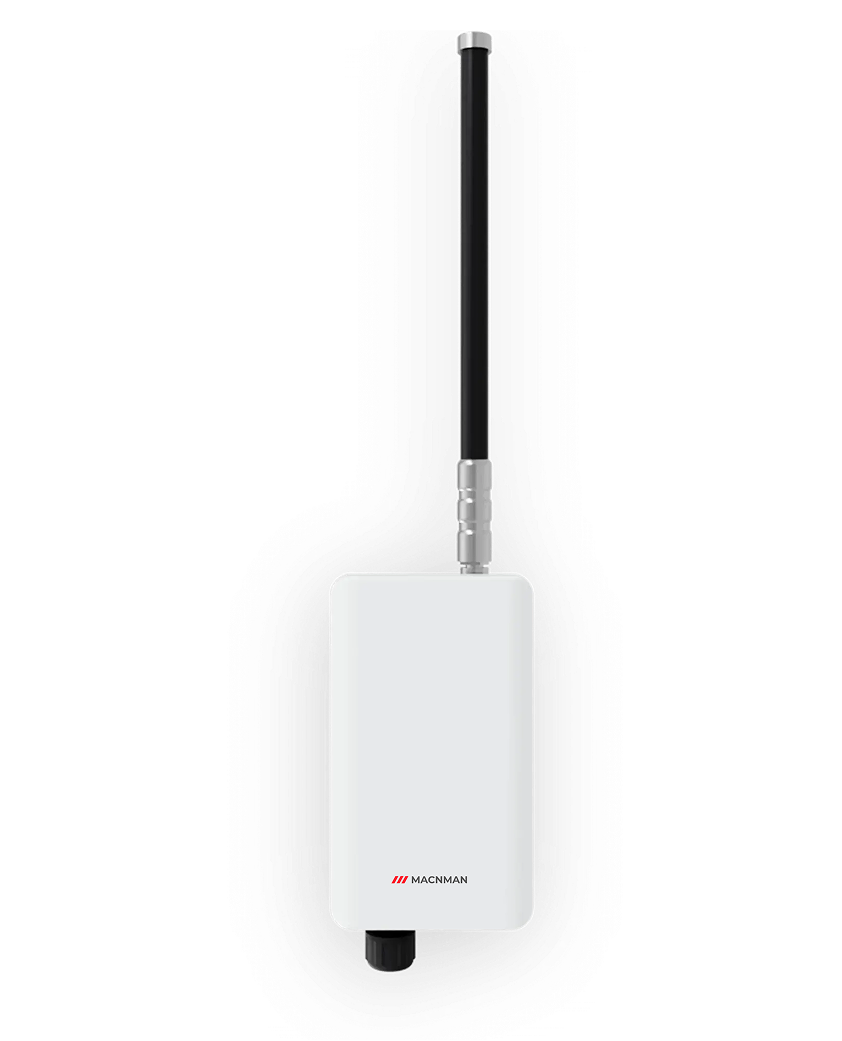

LoRaWAN-Based Connectivity

Long-range, low-power wireless network enables reliable data transmission without Wi-Fi dependency.

- 03

Automated Alerts & Notifications

Instant alerts sent to the control room when harmful gas thresholds are crossed.

- 04

Seamless SCADA Integration

AQI data integrated directly into the warehouse’s SCADA dashboard for centralized monitoring

- 05

Low Power & Maintenance-Free

Sensors designed for years of operation with minimal servicing, ideal for remote or enclosed spaces.

- 06

Improved Workplace Hygiene & Safety

Prevents gas buildup and ensures a healthy, compliant environment for warehouse staff.

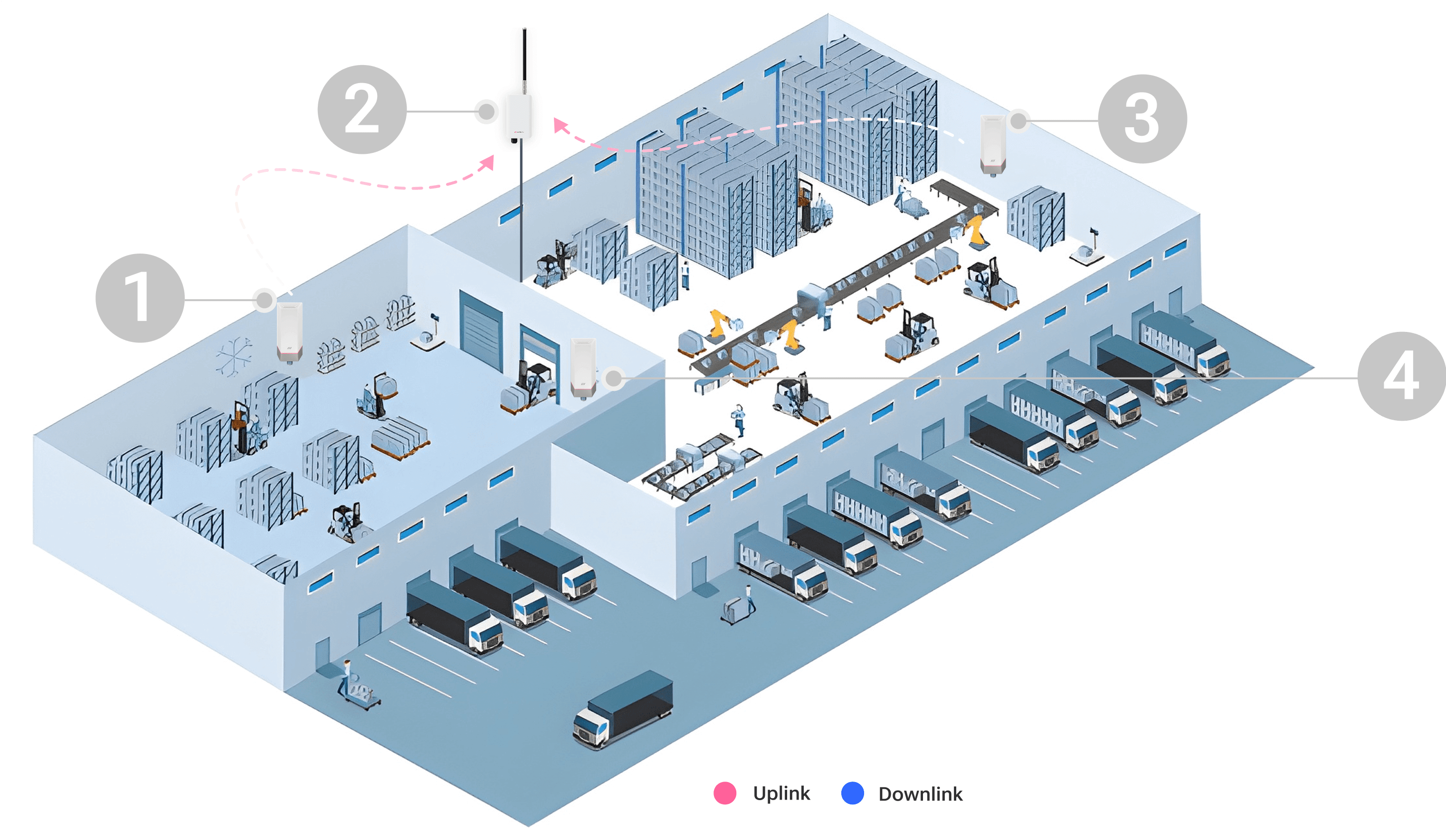

LoRaWAN System Architecture for Real-Time Warehouse Odor Monitoring

Deployment: Installing Odor Sensors Where It Actually Matters

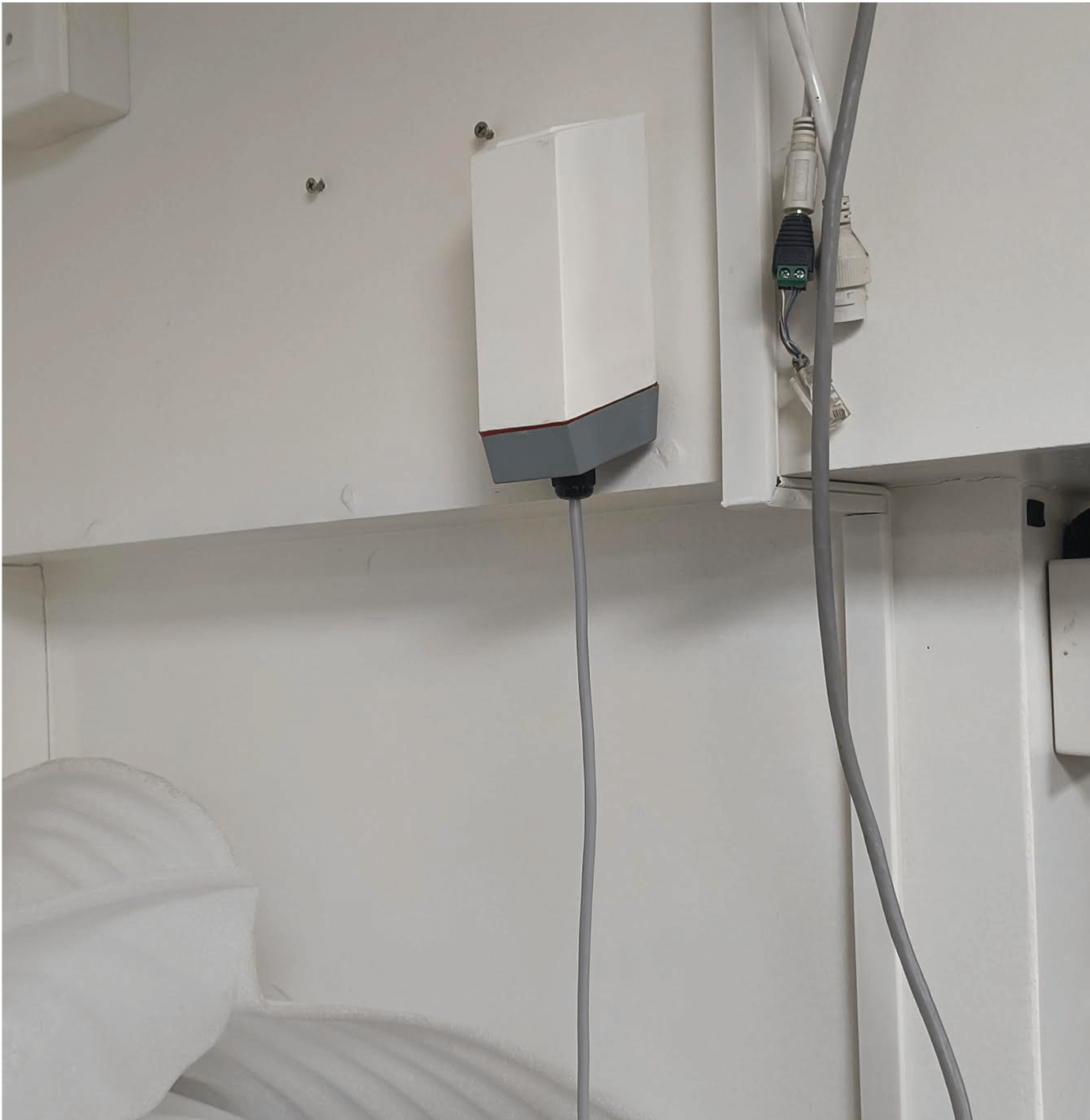

To make the setup practical for a fast-moving facility team, every sensor node included status light indicators for quick on-site validation (power / connectivity / normal vs alert state). This meant the team didn’t need to open a laptop or dashboard just to confirm if the sensor is alive they could verify health instantly during routine checks while the backend continuously logged data for trend analysis and hotspot identification.

MacSync LoRaWAN AQI Node

Mounted near drainage and cleaning areas to identify ammonia buildup from cleaning agents and waste residue.

Industrial LoRaWAN Gateway

Provided long-range data transmission across the entire warehouse complex, ensuring seamless cloud connectivity and backup storage..

SCADA Dashboard

All devices communicated through Macnman’s secure LoRaWAN network, with data forwarded to the SCADA dashboard.

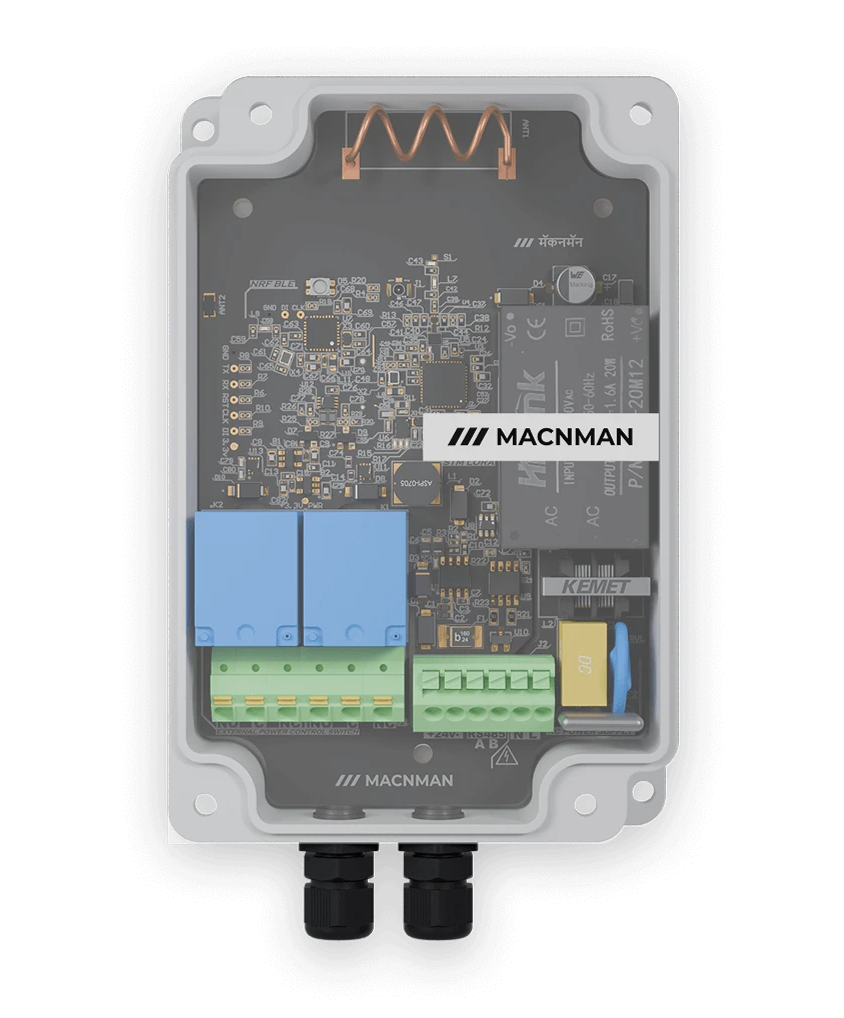

MacSet Controller with Andon Light

Installed outside washrooms and at key measuring points to provide visual alerts whenever gas concentrations exceed safe thresholds.

Challenges: Deploying LoRaWAN Network Coverage in a Massive Warehouse

Accurate Sensor Calibration

H₂S, NH₃, and CO₂ sensors needed precise field calibration to maintain reliable readings under varying humidity and temperature conditions.

Visual Alert Integration

Synchronizing the MacSet Andon lights with sensor thresholds required careful configuration to avoid false alerts and ensure timely staff response.

Long-Term Reliability

Ensuring continuous operation with minimal maintenance while maintaining battery life and sensor accuracy in high-traffic areas.

Data Consistency

Integrating real-time sensor data with the warehouse’s SCADA dashboard demanded robust network management and redundancy measures.

Validation: H2S & NH3 Monitoring Verified Across Washroom Zones

Sensor Accuracy Verification

H₂S, NH₃, and CO₂ sensors were calibrated and tested to maintain ±2% measurement accuracy in varying humidity and temperature.

LoRaWAN Connectivity Testing

Long-range network coverage and data transmission were validated across all washrooms and service areas, ensuring zero communication gaps.

Alert System Validation

MacSet Andon lights and SCADA notifications were tested to confirm instant response when gas concentrations exceeded thresholds.

Integration Testing

End-to-end verification confirmed seamless synchronization between sensors, LoRaWAN gateway, and the facility’s SCADA dashboard.

Impact: Cleaner, Safer, and Smarter Warehouses

Real-Time Air Quality Visibility

Facility managers now monitor H₂S, NH₃, and CO₂ levels instantly across all washrooms.

Automated Safety Alerts

MacSet Andon lights and dashboard notifications ensure immediate action when gas levels exceed safe thresholds.

Data-Driven Hygiene Management

Cleaning schedules are now optimized based on live air quality data, reducing resource wastage.

Low Maintenance & Scalable

LoRaWAN-enabled devices operate long-term with minimal upkeep, allowing easy expansion to other warehouse zones.

Conclusion: Smart Monitoring, Not Guesswork

This Amazon warehouse deployment wasn’t just about installing odor sensors it was about giving the facility team control. By combining H2S and NH3 odor monitoring with a warehouse-wide LoRaWAN network, we turned a “washroom smell problem” into a system that can be measured, validated, and improved every single day.

The real value we added was simple but powerful: visibility + actionability. Instead of chasing complaints, the team can now detect odor spikes early, identify the exact hotspot zone, and respond with the right corrective step at the right time. That’s what smart monitoring should do in real industrial environments reduce uncertainty, protect comfort, and keep operations running smoothly.

Unlock the next real-world IoT deployment for Your Warehouse