UWB Forklift Tracking for Real-Time Inventory Movement and Smart Task Allocation

Warehouses don’t struggle because people aren’t working hard.

They struggle because too many decisions are made without visibility.

Forklifts are moving all day put-away, picking, replenishment, staging, dispatch support & yet, in many warehouses, the most common questions are still:

- “Where is the nearest forklift?”

- “Who is free right now?”

- “Did that pallet reach the staging zone?”

- “Why is dispatch waiting?”

This is where the real operational pain begins.

Because when forklift movement and inventory movement are not visible in real time, the warehouse starts running on assumptions, phone calls, and manual coordination.

It works when the load is low. But as soon as volumes increase, this turns into daily delays, wrong placement, and missed timelines.

That’s why this problem is important to solve.

A warehouse doesn’t fail in one big moment.

It loses money in small losses repeated every day search time, waiting time, re-check time, wrong movement, and task confusion.

This case study covers how we addressed that using a UWB-based forklift tracking system, combined with inventory movement visibility and smart task allocation.

The Problem: Slow Response & Idle Waiters

In a fast-moving warehouse, forklifts are the real execution engine every put-away, replenishment, picking, and dispatch task depends on them. But when forklift movement isn’t visible in real time, the entire operation starts running on assumptions, radio calls, and manual coordination. The customer was facing daily delays simply because there was no clear answer to basic questions like where the nearest forklift is, which operator is free, or whether inventory actually reached the staging area.

No Real-Time Forklift Visibility Indoors

No real-time indoor forklift location visibility for supervisors

Untracked Inventory Movement Between Zones

Inventory movement not traceable, leading to wrong placement and re-check cycles

Manual Task Allocation and Coordination Overload

Manual task allocation causing uneven workload and delayed priority jobs

No Clear Performance and Delay Insights

Lack of performance clarity, making it difficult to identify delays and improve operations

The Solution: Real-Time Forklift Tracking with Smart Task Allocation

To solve the visibility and execution gap inside the warehouse, we proposed a UWB-based forklift tracking and warehouse task allocation system built specifically for indoor operations where GPS fails. The goal was simple: give supervisors and operations teams a live view of forklift movement, inventory flow, and task progress so decisions are based on real-time data, not assumptions.

This solution doesn’t just “track forklifts”. It creates a structured workflow where forklifts, inventory zones, and tasks are connected in one system. The result is faster task execution, fewer misplaced pallets, smoother dispatch operations, and a warehouse that becomes easier to control and scale.

- 01

UWB Personal Trackers for Every Waiter

Managers could instantly see who is free, who is busy, and who is closest to a guest request.

- 02

Instant Visibility for Supervisors

Managers could instantly see who is free, who is busy, and who is closest to a guest request.

- 03

Automatic Idle Zone Detection

The system highlighted idle pockets so staff could be redirected during peak hours.

- 04

Zone Coverage Monitoring

Ensured no table or section was left unattended.

- 05

Real-Time Heatmaps for Shift Optimization

Showed where waiters spent time, helping fix slow-response zones quickly.

- 06

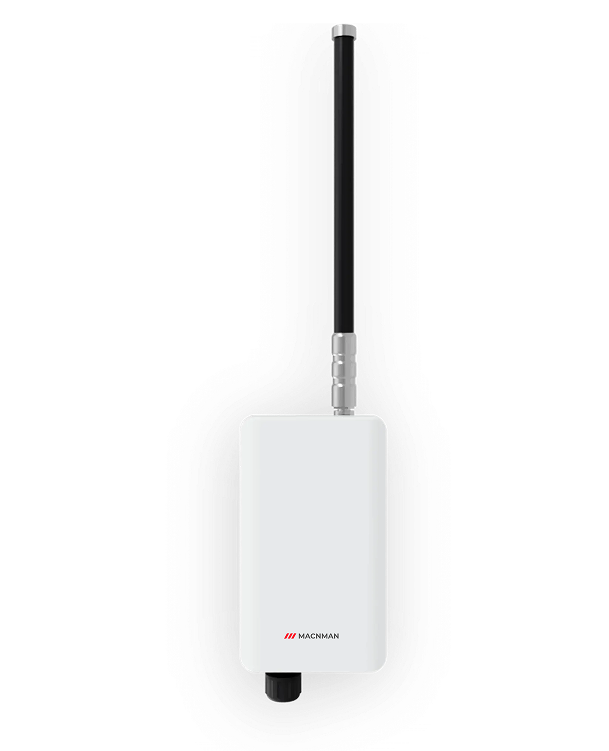

Reliable Power & Enclosure

IP67-rated, solar-assisted setup ensures continuous operation in harsh conditions.

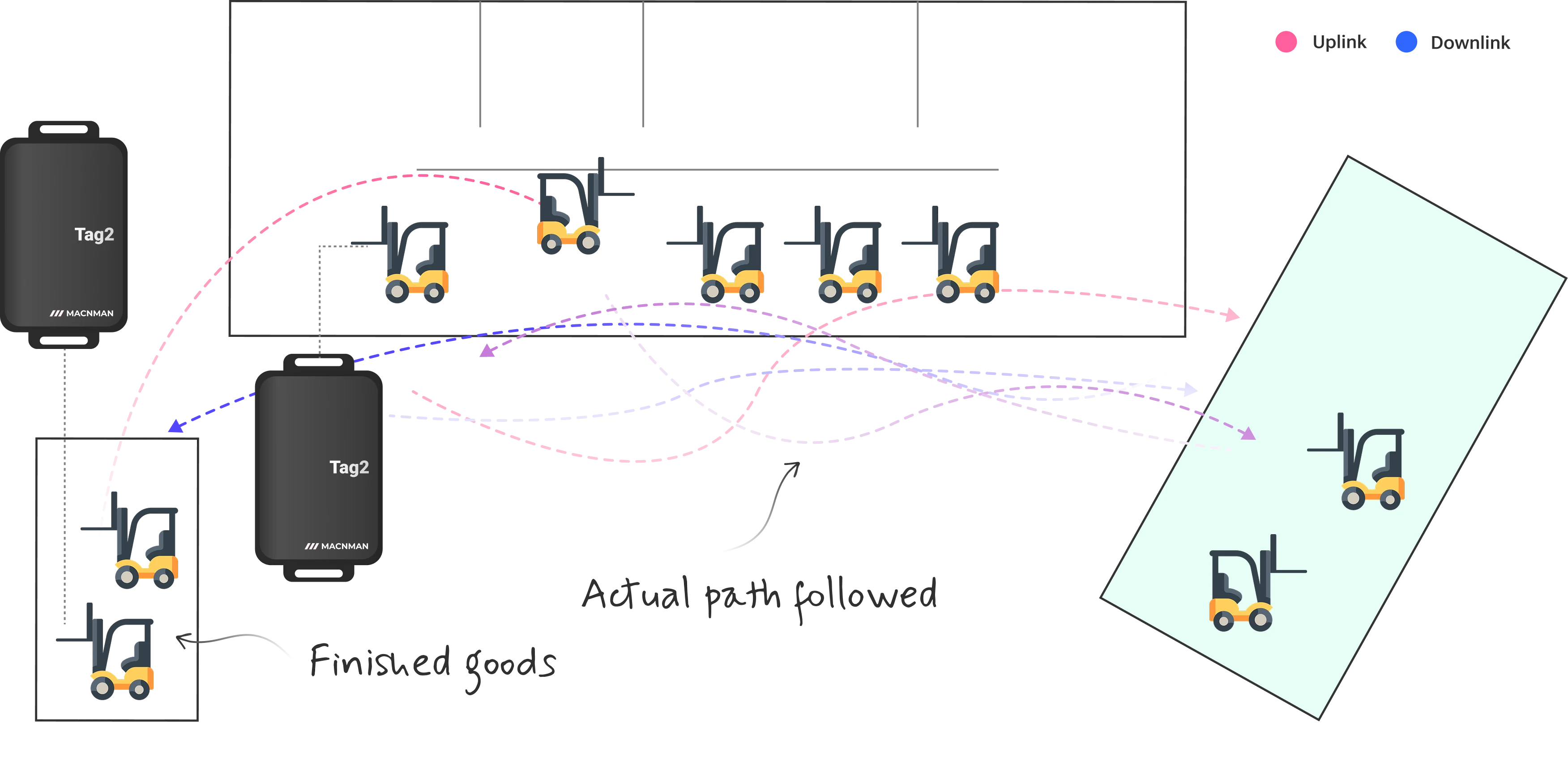

UWB Forklift Tracking System Architecture for Real-Time Warehouse Operations

Deployment: UWB Forklift Tracking Across a Large-Scale Warehouse

Deploying the UWB forklift tracking system inside a live warehouse was not just an installation job it required real engineering on the floor.

The first challenge was zone mapping, where we digitally defined receiving, storage aisles, staging, and dispatch areas so forklift movement could be tracked in a way that matches real warehouse workflows.

Next came location calibration, because indoor accuracy depends heavily on anchor placement, reference points, and fine-tuning until tracking remains consistent across the entire layout.

Since warehouses are full of metal racks and moving equipment, signal reflections and multipath interference were also a major factor, so we had to optimize the setup to ensure stable positioning even in high-reflection zones. Alongside UWB, we also planned and deployed a large-scale LoRaWAN network across the plant, ensuring reliable wireless coverage and scalability for industrial-grade operations without disrupting daily production movement.

UWB Anchors

Creates the indoor positioning grid that enables high-accuracy forklift location tracking across warehouse zones.

UWB Trackers

Continuously transmits real-time location data, making forklift movement visible and traceable indoors.

Central Monitoring Dashboard

Converts live tracking into actionable operations: task allocation, zone visibility, movement history, and supervisor control.

LoRaWAN Gateway

Provides long-range, reliable plant-wide connectivity to scale monitoring and integrate additional industrial devices across the facility.

Overcoming Industrial Weather Monitoring Challenges

Zone mapping in a running warehouse

Ensuring stable LoRaWAN connectivity across dense city infrastructure for reliable weather data.

Achieving stable UWB location calibration

Calibration required multiple iterations to maintain consistent accuracy across all aisles and bays.

Managing reflections from metal racks and moving forklifts

Sensors calibration was needed to ensure real-time accuracy for temperature, humidity, and rainfall data.

Maintaining reliable wireless connectivity across the entire plant

Network planning was critical to ensure uninterrupted data flow at large scale.

Validation: How We Ensure Industrial Weather Station Data Accuracy

Data Accuracy and Benchmarking

Before deployment, every sensor was individually calibrated in a controlled lab environment against a certified reference instrument

Co-Location Benchmarking

In the field, one of our LoRaWAN nodes was co-located next to a high-end, traditional wired meteorological station used by the local authority.

Network Reliability and Operational Metrics

The long-term value of an industrial IoT weather station hinges on its consistent, autonomous operation

Reduced Field Maintenance

The static (non-moving part) design of critical sensors, such as wind speed/direction, has been validated to eliminate the need for yearly mechanical calibration

Impact of Industrial Weather Station for Smart Factories & Production Efficiency

95% Reduction in Maintenance Costs

LoRaWAN's low power consumption allows stations to run autonomously for up to 5 years on a single battery, eliminating frequent service trips.

Real-Time Microclimate Hazard Alerts

Instant, location-specific data on wind and precipitation drives immediate action, preventing costly operational downtime and ensuring site safety compliance.

60% Faster Critical Data Latency

Data-driven decisions improve traffic, energy, and public services efficiency.

Seamless SCADA/IoT Integration

Standardized APIs allow for plug-and-play integration with existing SCADA, analytics, and data management platforms in less than 72 hours.

Conclusion: Transforming Industrial Operations with LoRaWAN Weather Monitoring

The implementation of the industrial weather station based on LoRaWAN has fundamentally reshaped our client's approach to environmental risk management and operational efficiency. This solution successfully transcends the limitations of legacy monitoring systems by delivering an unparalleled combination of performance, cost savings, and data quality.

Ready to Transform Your Industry with IoT?