Industrial Air Quality Monitoring Using LoRaWAN Outdoor AQI Sensors

In industrial plants, air quality isn’t something you check once a day it changes hour by hour. A small rise in dust, smoke, or outdoor pollution can quickly turn into an unsafe working condition, especially in open-yard areas where workers are constantly moving between zones.

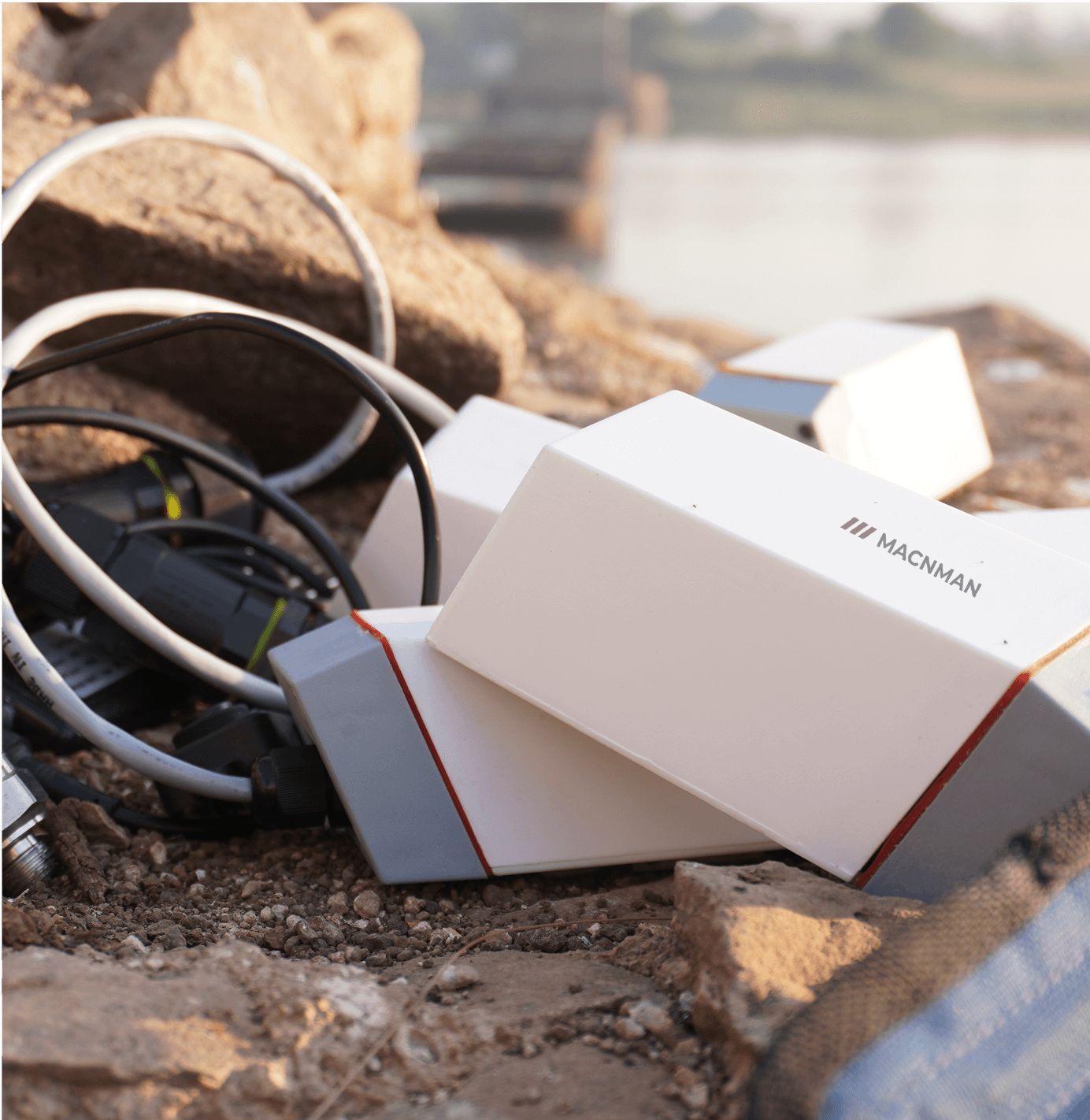

To make air quality measurable and controllable, Macnman Technologies deployed LoRaWAN-based outdoor AQI monitoring sensors across the industrial site. These sensors continuously track real-time air conditions and pollution trends, giving the safety and operations teams clear visibility into when AQI levels rise, which zones are impacted, and when action is required. The result is simple: safer work conditions, faster decisions, and industrial air quality monitoring that works reliably on-ground.

Problem: Air Quality Compliance Without Real-Time AQI Visibility

For industrial plants, air quality is not just about comfort it’s a worker safety & compliance requirement. The client needed a reliable way to ensure outdoor work zones stayed within acceptable limits and to maintain proof for safety reviews and compliance audits. But the biggest gap was simple: no continuous AQI visibility across the site.

Without real-time outdoor AQI monitoring, the team was forced to depend on manual checks and delayed observations.

Unreliable Weather Data

Manual or outdated monitoring caused unexpected downtime.

Equipment Vulnerability

Lack of real-time alerts put machinery at risk from extreme conditions.

Production Inefficiency

Poor weather insights led to suboptimal operational planning.

Compliance Risks

Failure to monitor conditions affected safety and environmental compliance.

Solution: LoRaWAN Outdoor AQI Monitoring for Industrial Compliance

To close the compliance and safety gap, we proposed a LoRaWAN-based outdoor AQI monitoring system designed for industrial environments. By installing outdoor AQI sensors at key locations across the plant premises, the client gets continuous real-time visibility of air quality conditions instead of relying on manual checks or delayed reporting.

With long-range LoRaWAN connectivity, the sensors reliably push AQI data to a central monitoring layer where the safety team can track live AQI status, pollution trends, and abnormal spikes by zone. This makes compliance practical: the plant can take faster corrective action when air quality degrades and maintain a clear history of outdoor AQI performance for safety accountability and audits.

- 01

Multi-Sensor Integration

Monitors temperature, humidity, pressure, and wind conditions in real-time.

- 02

LoRaWAN Connectivity

Enables long-range, low-power communication from remote industrial sites.

- 03

Centralized Dashboard

Displays live data and historical trends for operational decision-making.

- 04

Automated Alerts

Sends notifications when environmental thresholds are exceeded.

- 05

Low Maintenance

Sensors are easy to install and running on the solar energy so overall maintenance cost of the system is low

- 06

Reliable Power & Enclosure

IP67-rated, solar-assisted setup ensures continuous operation in harsh conditions.

Architecture Diagram : From Outdoor Sensors to Live Compliance Reports

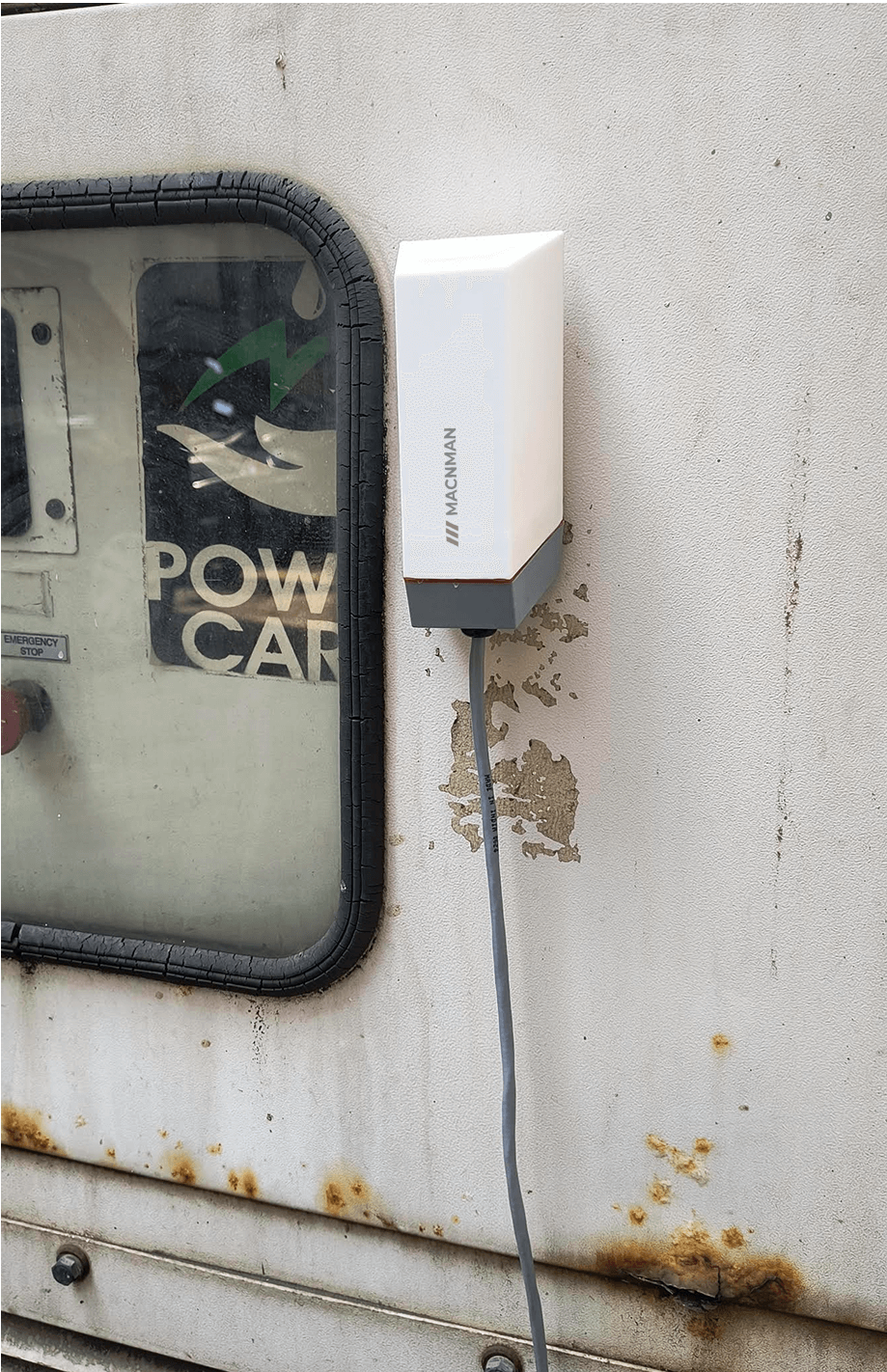

Deployment: Outdoor LoRaWAN AQI Sensors Installed Across Critical Plant Zones

The deployment started by identifying the outdoor zones that matter most for worker safety entry points, open work areas, loading/unloading zones, and locations where dust and emissions can fluctuate throughout the day. Outdoor AQI sensors were then installed at these critical points to capture real air conditions instead of average assumptions.

MacSync Weather Station

Mounted on a sturdy pole at an open field location to ensure unobstructed wind and sunlight measurements.

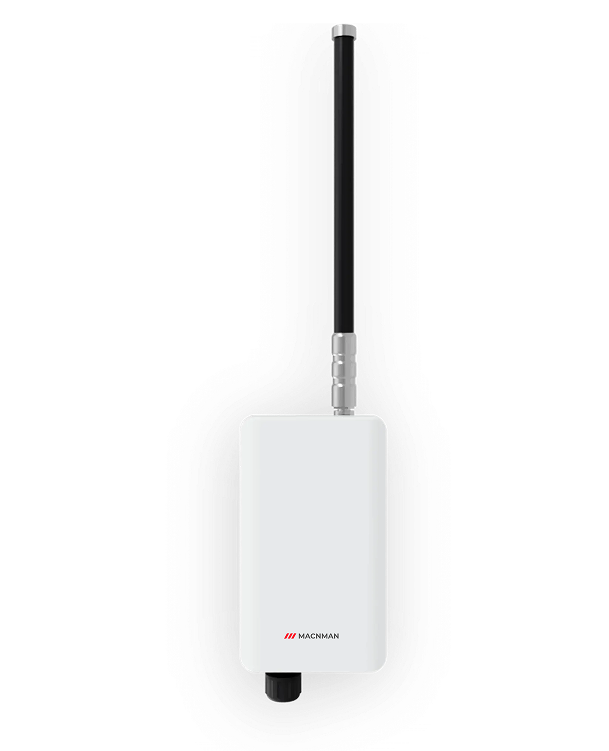

Industrial LoRaWAN Gateways

Positioned at central locations to collect data from all nodes and forward it securely to the cloud platform.

Central Monitoring Dashboard

Provided operators with live status, historical data, and performance analytics for parking utilization and sensor uptime.

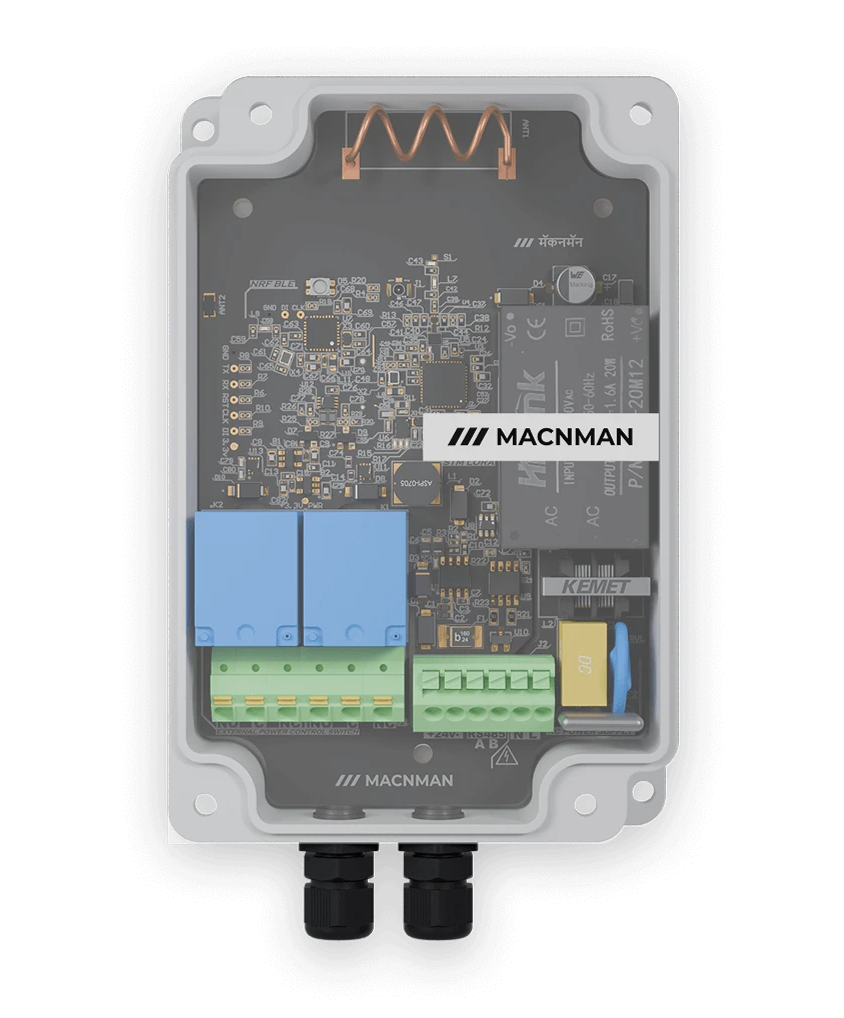

Industrial LoRaWAN Controller

Installed at the central rooms to give any alerts from the servers to teams in case of any parameters are crossing the thresholds.

Building Reliable LoRaWAN Coverage Across a Wide Industrial Site

Overcoming Urban Signal Barriers

Ensuring stable LoRaWAN connectivity across dense city infrastructure for reliable weather data.

Weatherproofing for Reliable Data

Protecting sensors from rain, dust, and extreme temperatures to maintain uninterrupted monitoring.

Sensor Accuracy & Calibration

Sensors calibration was needed to ensure real-time accuracy for temperature, humidity, and rainfall data.

Weatherproofing Protection

Continuous exposure to dust and moisture required rugged enclosures for long-term reliability.

Testing & Validation: Verified AQI Data Accuracy and LoRaWAN Network Reliability

Data Accuracy and Benchmarking

Before deployment, every sensor was individually calibrated in a controlled lab environment against a certified reference instrument

Co-Location Benchmarking

In the field, one of our LoRaWAN nodes was co-located next to a high-end, traditional wired meteorological station used by the local authority.

Network Reliability and Operational Metrics

The long-term value of an industrial IoT weather station hinges on its consistent, autonomous operation

Reduced Field Maintenance

The static (non-moving part) design of critical sensors, such as wind speed/direction, has been validated to eliminate the need for yearly mechanical calibration

Impact: Safer Working Conditions with Real-Time Outdoor AQI Visibility

95% Reduction in Maintenance Costs

LoRaWAN's low power consumption allows stations to run autonomously for up to 5 years on a single battery, eliminating frequent service trips.

Real-Time Microclimate Hazard Alerts

Instant, location-specific data on wind and precipitation drives immediate action, preventing costly operational downtime and ensuring site safety compliance.

60% Faster Critical Data Latency

Data-driven decisions improve traffic, energy, and public services efficiency.

Seamless SCADA/IoT Integration

Standardized APIs allow for plug-and-play integration with existing SCADA, analytics, and data management platforms in less than 72 hours.

Conclusion: Transforming Industrial Operations with LoRaWAN Weather Monitoring

This project proved that industrial air quality can’t be managed with assumptions it needs real data, in real time. By deploying LoRaWAN-based outdoor AQI monitoring sensors across the plant, we gave the client continuous visibility into changing air conditions and the ability to act before pollution levels affect daily work.

The real value wasn’t just compliance reporting it was improving the everyday experience of people on-site. With live AQI awareness, teams could work with better comfort, reduced exposure risk, and higher confidence that the environment is safe. That’s the impact Macnman aims for: industrial monitoring that protects people, not just processes.

Ready to Transform Your Industry with IoT?