Long-Distance Conveyor Belt Monitoring with Andon Lights, Start/Stop Control & LoRa Hops

When a conveyor belt runs for kilometers, the problem is never the belt alone.

The real pain starts when something fails in the middle of nowhere and the team has no idea where it happened.

In this project, the conveyor line stretched across a long route through forest terrain, and the customer’s team was spending hours just to locate the issue. Power cable breakage, sensor faults, and stop events were turning into long downtime windows because troubleshooting was completely manual.

Macnman Technologies solved this by building a long-range monitoring and control layer using LoRa network hopping over 18 KM, integrating directly with existing RS485 sensors, start/stop buttons, and andon lights installed along the conveyor belt. The result: faster fault identification, reduced downtime, and real operational visibility across the full conveyor length.

Problem: 18 KM Conveyor Belt Failures With Zero Visibility

When a conveyor belt runs for kilometers, even a small fault becomes a major downtime event. In this case, the biggest issue wasn’t only breakdowns — it was the time wasted just to find where the problem happened. Power cable breakage, stop events, and sensor issues could occur anywhere across the long route, and the maintenance team had to physically travel and inspect section by section.

With no real-time conveyor belt monitoring, every failure turned into a manual hunt. The customer team was losing hours in troubleshooting, response time was slow, and production suffered because critical signals from RS485 sensors, start/stop buttons, and andon lights were not available centrally when they were needed the most.

No Real-Time Control

Each checkpoint had manual RS485 buttons that could only be triggered on-site. Starting or stopping the conveyor meant physically traveling kilometers across the jungle.

Communication Gaps

The main control room sat nearly 18 km away, and no wired or cellular network could sustain that distance reliably.

High Maintenance Costs

Frequent breakdowns and cable faults turned simple restarts into hours of downtime and loss of productivity.

Safety Risks

Delayed responses during belt jams or overloads put both equipment and personnel at risk.

Proposed Solution: Long-Range Conveyor Belt Automation Without New Cabling

To eliminate the blind spots across the conveyor route, we proposed a LoRa-based long-range monitoring and control network designed to work across the full 18 KM conveyor belt line, even through forest terrain. Instead of depending on continuous cabling or manual inspection, the system uses network hopping to carry critical signals from remote conveyor zones back to the central monitoring point.

The solution integrates directly with the existing RS485 sensors, along with start/stop buttons and andon light status, so the customer gets real-time visibility of conveyor health and events without changing the core infrastructure. With this setup, faults like power cable breakage or stop triggers can be detected and localized faster reducing downtime, improving response time, and making long conveyor belt operations easier to manage every day.

- 01

Long-Range LoRaWAN Connectivity

A seamless long-range network connected all conveyor checkpoints to the central room, spanning 22 km through dense terrain.

- 02

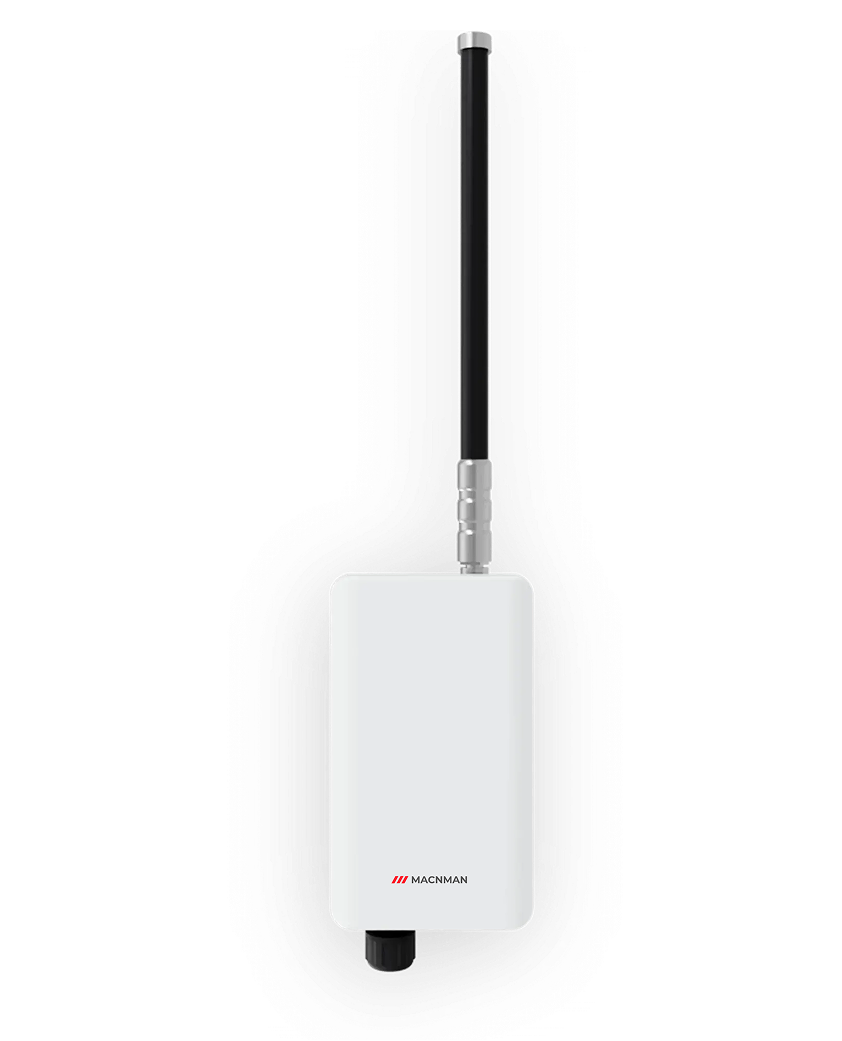

MacSync RS485 Nodes

Each unit linked with existing RS485 panels, instantly converting manual push-button points into wireless LoRaWAN nodes

- 03

Central LoRaWAN Gateway

A rugged LoRaWAN gateway captured signals from all nodes and transmitted them to the SCADA room 18 km away.

- 04

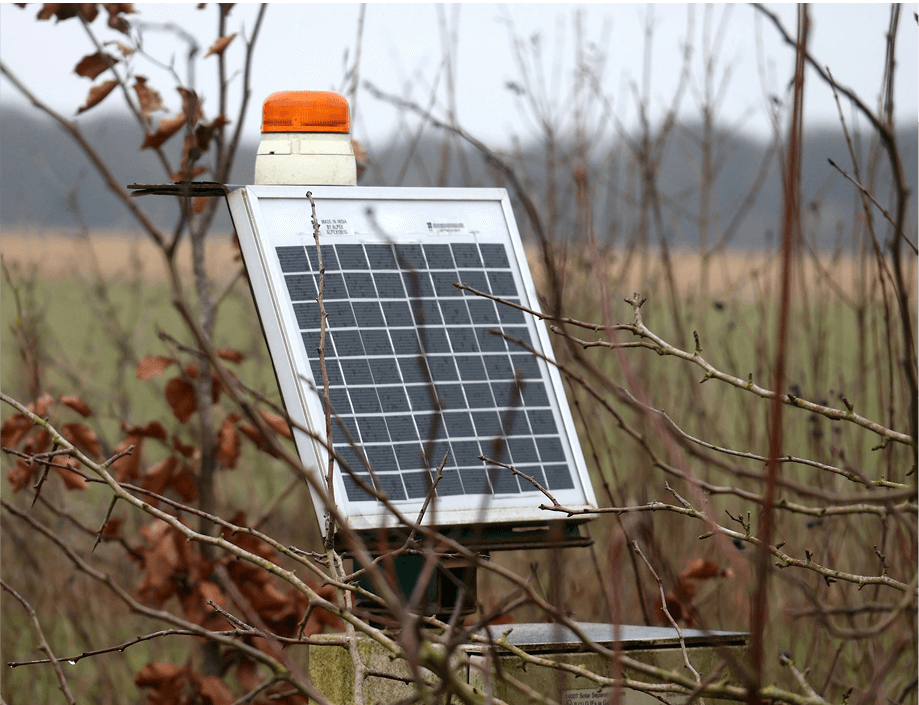

Andon Indicators

Bright Andon lights gave instant visual confirmation of commands and operational status at each checkpoint.

- 05

SCADA Integration

The entire system synced with the mine’s SCADA interface, enabling remote control, monitoring, and event logging.

- 06

Low-Power Design

Ultra-efficient MacSync nodes ensured years of operation with minimal maintenance ideal for remote, harsh environments.

Architecture Diagram: 18 KM Conveyor Belt Monitoring System Using LoRa Network Hopping

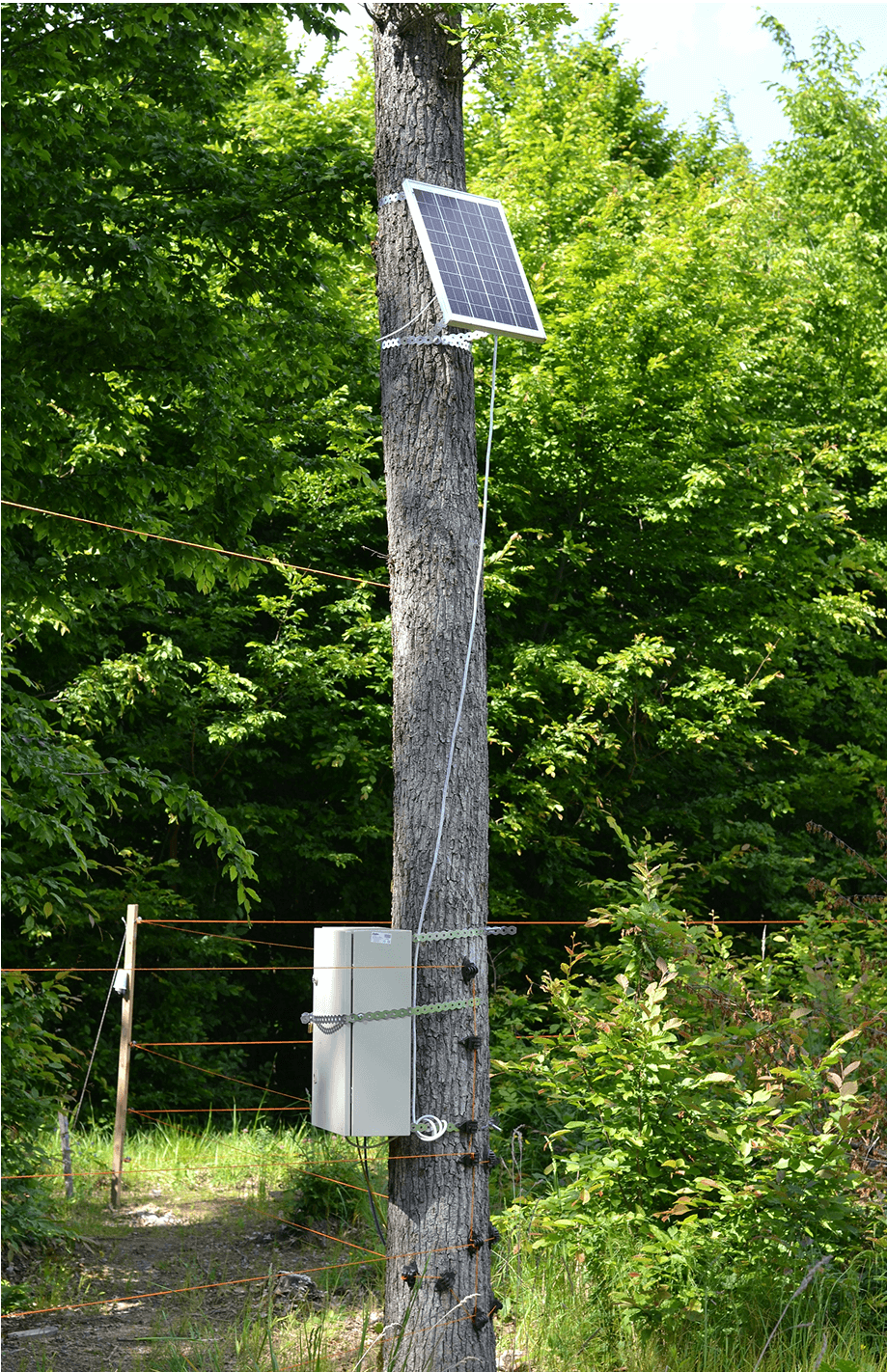

Deployment: Connecting Remote Conveyor Zones Through Forest Terrain

Deploying a monitoring network across an 18 KM conveyor belt line is not a normal installation especially when the route passes through forest terrain and remote zones. Instead of trying to force a single-point connection, we deployed the system using LoRa network hopping, creating a reliable communication path across the entire conveyor length.

At each critical point, we integrated the MacSync controllers with the existing RS485 sensors, along with start/stop buttons and andon light status signals. This ensured that every stop event, fault indication, or abnormal condition could be captured from the exact section where it occurred and pushed back to the central monitoring point. The result was a deployment built for real operations: long-range connectivity, minimal new wiring, and faster fault localization across the full conveyor route

MacSync LoRaWAN Node (RS485)

Converted legacy wired systems into smart, wireless endpoints with real-time communication..

Industrial LoRaWAN Gateway

Central communication hub ensuring reliable long-range connectivity through the jungle terrain.

SCADA System Interface

Centralized data visualization and full remote control capability.

Andon Light Indicators

Provided quick on-site indication to maintenance teams, reducing response time and manual checks.

Deployment: Long Conveyor Connectivity Built in Real Terrain & Jungle

Long-Range Connectivity 📡

The control room sat 18 km from the farthest checkpoint, and jungle vegetation blocked direct signals.

Legacy RS485 Integration ⚙️

Configuring MacSync nodes to convert them into wireless endpoints required careful mapping, calibration, and protocol tuning.

Environmental Stress 🌦️

Rugged IP67 enclosures and vibration-resistant mounting kept the nodes and controllers operational.

Multi-Hop Signal Optimization 🔗

We implemented multi-hop routing to ensure every checkpoint stayed connected without signal loss.

Validation & Validation: Verified Data Flow from Andon to Control Room

Connectivity & Signal Strength 📡

Verified end-to-end LoRaWAN communication from the farthest checkpoint to the central gateway.

RS485 Data Accuracy ⚙️

Tested all existing push-button panels connected via MacSync nodes.

Andon Light Response 💡

Simulated conveyor faults & remote start/stop scenarios.

SCADA Integration Verification 📊

Validated real-time data sync between LoRaWAN network and the control room SCADA system.

Impact: Faster Fault Detection and Reduced Downtime Across 18 KM Conveyor Operations

Reliable Remote Control ⚡

Operators in the control room, 18 km away, can start, stop, and monitor each checkpoint without traveling into the jungle.

Reduced Downtime ⏱️

Operators in the control room, 18 km away, can start, stop, and monitor each checkpoint without traveling into the jungle.

Seamless SCADA Integration 📊

All LoRaWAN nodes communicate with the existing SCADA system, providing centralized monitoring.

Enhanced Safety 💡

Immediate Andon light signals reduce manual interventions and keep personnel away from moving conveyors

Conclusion: From Manual Troubleshooting to Real-Time Control

This project proved that long conveyor belt operations don’t fail because teams don’t work hard — they fail because the system gives them no visibility. By building an 18 KM LoRa network hopping communication layer and integrating it with existing RS485 sensors, start/stop buttons, and andon lights, we turned a remote conveyor line into a connected operation.

The real value was simple: faster fault identification, reduced downtime, and less wasted manpower. Instead of spending hours searching for a cable break or stop event, the customer team could pinpoint the exact section and respond immediately. That’s what Macnman delivers — industrial connectivity that works in real terrain, not just inside a lab.

Read Rohit's perspective on the smart BMS solution for tracking & safety